MG-Cars.info

MG Midget and Sprite Technical Front suspension alignment problem BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG Midget and Sprite Technical - Front suspension alignment problem

| Hi I've got an alignment problem with the LHS front suspension and am looking for some advice on what to do. Based on a 90s Heritage shell when I originally built up the suspension I bolted on the lower pan / stub axle first and then offered it up to the shock absorber. However, the top trunnion overlapped the end of the shock absorber arm rather than being next to each other. Following advice I was given at the time I was able to apply pressure so that they sat flush with each other and bolted them together. Over time this forced the pivot arm out of the shock absorber body (see pic) as the stub axle is applying forwards force on the shock absorber arm. I've replaced the lower pan and checked that the shock absorber arm was pressed correctly in the body but it's just happened again :-( So, any thoughts on why this could be happening / what to do ? thanks

|

| D Griffiths |

| What a sad photo... it appears you will need a replacement lever shock Without seeing your front suspenstion Im only going to take a guess and suggest the ( trouuin )..sorry misspelled)) link is 180 degree backwards. Someone posted a perfect photo today that shows what I mean, give a bit of time to find it Prop |

| Prop and the Blackhole Midget |

| Okay... hopfully this will work http://www2.mg-cars.org.uk/cgi-bin/gen5?runprog=mgbbs&access=&mode=imgdis&ifile=297_0_61511374900012_1399985222.jpg If the photo comes up, it should be a photo looking down on the trioun link, with the lever arm attached to the side...notice the postion of the center vertical nut as it relates to the lever with the castle nut on the side....the castle nut is in front of the center vertical nut, my guess your nut is behind the vertical nut ....meaning the truion link is backwards by 180 degrees Hope that makes scence If your set up is correct take some photos so we can all see.them Agian im only guessing what is the issue...until theres photos, I can only go with the common fault recommendations Prop |

| Prop and the Blackhole Midget |

| Ignore what Prop says. ;o) Was the shell new when you built it up? When you replaced the wishbone pan, was there still the alignment issue? |

| Dave O'Neill2 |

| I'l second what Dave said. Nothing to do with which way round the trunnion is. More likely that the pin in the bottom of the wishbone pan that holds the kingpin on is not at right angles to the wishbone pan, meaning when the kingpin is on then it's not vertical and misses the trunnion. You've done well to do that to the damper, mostly it just wears the threaded bearing out at the bottom! I would check the alignment between the wishbone and the kingpin (even though you say you have a new wishbone pan) as a first step. I suspect that now that the damper has come apart like that it's not going to want to stay together any more. |

| Rob Armstrong |

| HI, tks for the comments. Yes the shell was new - I've not used the car much in recent years so it took a while to come apart. Last year I replaced the lower pan with a Barry King one and the alignment is the same. All the parts are assembled the right way round. I think this leaves: - shell incorrectly welded causing the alignment issue - the hole at the bottom of the king pin is machined incorrectly (this would cause bad alignment between wishbone and kingpin), I'm assuming the king pin itself must be straight otherwise the stub axle wouldn't turn. - shock absorber casing incorrect but this seems unlikely Also I had to fit 8" springs to get a standard ride height and the camber is 1.3 and 1.2 degrees positive (recently checked) so I think that there is an issue with how the shell was put together....but I'm trying to convince myself it's something simple before I go down that route !!!! |

| D Griffiths |

| i'll check mine later as my car is a reshell. . .I went for the frontline set up though, but will have a nosey to see if there is anything I can add |

| P Bentley |

| I think someone else on this board had a similar problem and it turned out to be a bent shock arm. IIRC there were pictures showing the bent arm versus the correct arm. The little "slip" pin inside the shock has likely been destroyed and needs to be replaced. I'd say it is time for a damper rebuild. |

| Trevor Jessie |

| Thanks again - I've ordered a recon shock so that I can get it on the road again whilst it's sunny and rule that part out of the problem. Any suggestions as how to measure the wishbone / kingpin alignment at home? I'm not online for a few days so I'll catch up with any comments at the weekend. |

| D Griffiths |

| " Any suggestions as how to measure the wishbone / kingpin alignment at home?" Yes, if the upper trunion lines up with the damper arm, it is in alignment if it does not, even with the replacement damper (with, presumably, a good arm on it), then either the a pan is bent, or the fixing points to the body are welded on wrong If you want to check the body fixing points, make sure the car is jacked up perfectly level and has a very flat floor under the front suspension, then measure from the ground to the points on the "good" side, compare them to the side in question and see if there is a difference. Norm |

| Norm Kerr |

| Yeah... im sure im wrong if the troiuin link was 180 degrees backwords, this damage wouldnt have occured as everone pointed out... it wont cause any damage at all just keep driving it, esp with the new shock....it will just look funny thats all Sorry for me being the idiot. Happy high speed driving Prop |

| Prop and the Blackhole Midget |

| I've found that often there is a degree of misalignment when fitting up the suspension - lots of rubber bushes not fully seated etc - usually can be sorted with a little leverage - it then settles in O.K. There has been a lot of poor quality 'Newly' manufactured shockers (not refurbs)on the market - When I built mine up 7-8 years ago I went through the stock at the supplier and rejected many due to arms pushed on to varying depths/angle of arms etc. We have seen reports of arms working out from the casing as yours seems to have - this should not happen. Is it a case of another faulty shock absorber ? R. |

| richard boobier |

| My old re shelled car (94 shell I think) had that very problem. The shock to trunnion didn't line up and you had to force it into position. It didn't pull the shock apart though. But then I think I only did 4 or 5k in it. It also had positive camber on the same side that I had to correct with offset bushes. After a few years of trying I couldn't get the car to drive as well as my Sprite. The steering felt dead and no matter how much I tried to sort it the self centering was alway very poor. I've heard of other similar problems with the early shells. |

| john payne |

| I went looking for chassis measurements to check if your Heritage shell was made true, and I found a couple of things you can check:

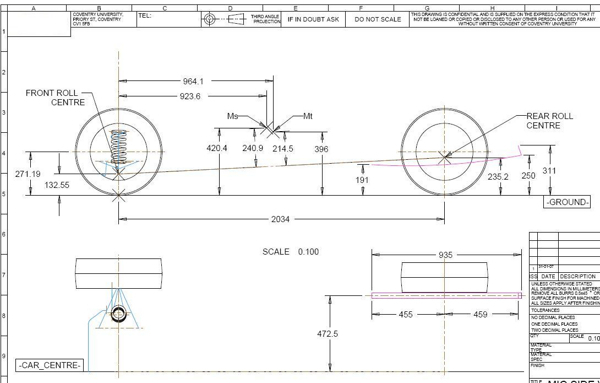

First - are the sills parallel to each other? Check this by setting the car up with one side dead level using a spirit level on the bottom of the sill, then see if the level shows any difference up at the other side. Next - check the kick-up of the front chassis rails is the same for both sides. Check each rail by running a straight edge or string line along the line of the rear half of the chassis rail where it merge into the floor and extend this line to the front of the car. At the front end of the chassis rail, the bottom of it should be 1" above the this line. A 1/4" difference between the heights of the rails could lead to 1/2" at the spring seats and 1" at the wheels. This 1" kick-up BMC adopted as a simple way of introducing castor to the front suspension. An alternative way to check the overall car is to set it up so that the front mounts of the rear spring are level (a spirit level blocked down from the plate by enough to clear the bottom of the bulge in the rear of the transmission tunnel) and compare for level with the rear shackle mounts at the back and the spring seats in the chassis at the front. This latter method is good for confirming the car is overall true or twisted, but does not tell you where if there is out of true between front of rear spring and the front spring mounts. The sill and chassis rail measurements above will give a good steer on this. I also found the attached, which someone had helpfully posted here a few years ago. But no one had the dimensions of the A Pan inner mounting points. Probably just check rh vs lh to make sure they are the same is enough, if your rails have the proper 1" kick up. Norm

|

| Norm Kerr |

| Norm I like your 2nd approach... esp with his shorter 8inch spring to help level the car out... that could really tie down some ideas, so much easier to look for level then read a flimsy 11 foot long tape measure Ive been looking but cant find the stock deminsions of the coil spring.... are they 9.25 inches tall... thats what I keep thinking It seems with that much damage in the tower (if thats where it is) id have thunk heritage would have caught that before leaving the factory...thats alot out for what we are talking about Of coarse maybe the car is a 7:30 am JANUARY 2nd car You know there has to be several of thooose cars out there....haha Prop |

| Prop and the Blackhole Midget |

| D, Can we get some various photos of the suspention in question...looking forward to seeing you agian on the weekend P. |

| Prop and the Blackhole Midget |

| "been looking but cant find the stock deminsions of the coil spring"? '58 ~ '66 = 9.4" '66 ~ '72 = 9.59" '73 ~ '75 = 9.85" '76 ~ '79 = 10.2" Rate: 271 lb / in Wire dia 0.5" coil dia 3.625" Fitted length 7.08" (@750lb working load) Effective coils 7 Camber +1 deg Caster 3 deg Kingpin inclination 6.5 deg Toe 1/16 (+/-1/16)" There's books with this stuff in! Norm |

| Norm Kerr |

| I had this very problem with a heritage shell BMH 801051 bought in 91. It's a long story, form spring heights to setting it up on a Car-o-lina, letters to Moss (supplier) meetings with David Bishop, heritage director. Eventually they agreed there was an issue with the geometry of the RHS and Naylors in Shipley had a guy who cut the shocker mounting apart and welded it back. Then a span of 17 years, told you it was a long story. I fitted frontlines front suspension kit and poly bushes to the A pan. RHS was fine but LHS was a real struggle. Well the LHS had always been a struggle but rubber bushes are more flexible. The error on this side is the alignment of the bottom inner brackets on the chassis rail. Stick a long dowel through both eyes and you could see they don't line up. So when it goes together the A pan is on a twist. I had also found camber issue on this side too, and had used offset nylatron trunnions bush for some time but when fitting the frontline kit these were replaced with poly bushes. I even went to the extent of having the frontline pivot rewelded to try to compensate but it was not successful. so on rebuilding the car for the second time last year I wanted to get it all sorted. On stripping that side it was evident that the twist on the A pan had transferred that force to the pin at the bottom of the king pin wearing both the pin and the king pin bottom bush. It had also produced cracking along weld seams around the entire suspension mount. So it went back to Naylors. Alastair remembered the car, even dug out the paperwork from 1993/4. When they tried to fit the A pan I got a call saying it wouldn't fit. Which wasn't a surprise as I had told them it had this misalignment. So, fortunately, the guy who did the repair to the RHS was still around, but working for himself as a chassis specialist. He basically cut it all apart with a plasma? Cutter, fitted the suspension so everything lined up and the camber was correct and welded it back up. At £35 per hour that's £700 thank you very much. Drives lovely now. Mike |

| M Myers |

| Hi all. Tks again for the comments. I've just fitted the replacement shock and ..... it looks like it's done the job !!!! The top trunnion and shock arm fitted together with no effort rather than the long lever / force I used with the original one - which was new and not a recon one like the one I've just bought. I didn't compare the shocks in detail but the arms themselves were the same dimensions. I can only guess that where the arm pivots in the body wasn't correctly aligned and meant that the arm was sweeping too far back. Interesting history Mike, my shell was @ '92 and fingers crossed it'll now be OK once I sort out the camber. I'm using rubber bushes so there is some play there but the lower arm is a PITA to fit though it seems to fit OK. Whilst I didn't expect the shell to be perfection I thought that Heritage might at least have made sure that the chassis points were correct before sending them out. |

| D Griffiths |

| I know it doesn't help here but for others - my previous Spridget had an early (possibly very early) Heritage shell and I had no problems in this area at all |

| Nigel Atkins |

| That's a positive result. I recall I had to tempt the A pan into position with a jack to be able to push the final pin through, that was using rubber bushes. Of course there is then more wear. The camber is tricky to do much about. My LHS was 1.5 to 2 degrees positive. When it put the frontline kit on it went to dead plumb instead of 2 deg negative. The only way round it I found was using those offset nylatron bushes. As for Heritage, well, I was very disappointed, not only that they failed to produce shells that were dimensionally correct in the steering geometry, but also did nothing to contact customers who had them, like a recall. Not to mention the customer service was shocking. Happy driving. Mike |

| M Myers |

This thread was discussed between 13/05/2014 and 18/05/2014

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now