MG-Cars.info

MG Midget and Sprite Technical Rear brake back plate fault. A new one on me. BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG Midget and Sprite Technical - Rear brake back plate fault. A new one on me.

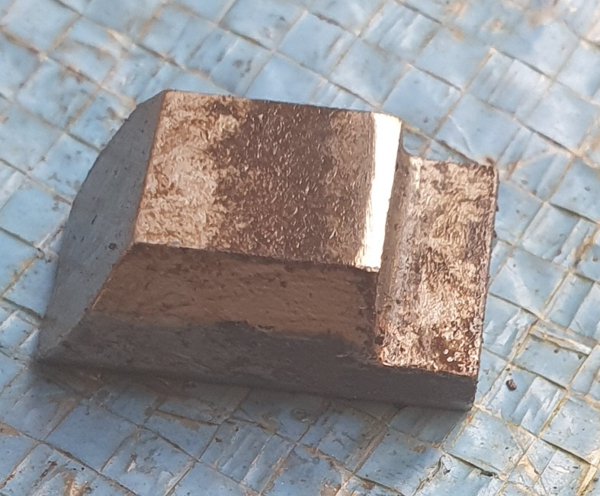

| Here's a new one on me. Never found this on a back plate before.

Unless I just haven't noticed it, and it's meant to be there to prevent over adjustment. But in 45 years, this has never happened to my brake adjuster before. When adjusting my rear brakes, it was getting increasingly hard to wind in the adjuster on one side. Plenty of meat on the shoes, and happening with both my old drum, and a new one. Pulled off the drum, removed the shoes from the wedge sliders, tried winding in the adjuster, and it was still hard. One of the sliders wasn't moving. It was 'locked' in place, by the force of the adjuster against it. The adjuster pushes against the wedge sliders, and forces them out against the shoes. But the adjuster also pushes the wedge end out towards the drum face. This tilts the slider as it pushes it out. This causes its front inner edge to dig into the channel it slides in. Because the sliders are hardened, they gradually create an edge in the base of the softer channel, that the slider gets caught on. Once I worked that out (assuming it's not by design), a small file removed the 'catch' in the channel, and a grinder on the leading edge of the slider, to create a slight chamfer, should make sure it doesn't happen again. Adjuster now winds out easily.

|

| anamnesis |

| Is this regardless of lubricating at services? |

| Nigel Atkins |

| Covered in copper grease these days, regular lithium grease before that. Plenty of lube. |

| anamnesis |

| In that case it must be you never go fast enough to move your rear brakes too much from their resting position, your old eyes are probably misreading the speedo, do you hear lots of people pressing their horns for Jesus and think you're near a church on your Sunday drives. 😁 Won't be long now, you'll be looking to swap onto a B. |

| Nigel Atkins |

| I doubt it's by design. Your fix will work but my guess is that the tunnel that the wedges move in was too slack, either from manufacture or subsequently from wear. I think maybe too much space for the wedge to slide in, allowing it to tilt outwards at the adjuster end, and causing the other end to dig in. Worth checking when replacing shoes and a 'light tap with a heavy hammer' on the outer face of the tunnel wouldn't go amiss. |

| GuyW |

| Yep I did wonder if the channel is too slack Guy. But that channel is a thick bit of metal, to have 'bent', and I'm not sure a gentle tap would do much to bend it back in, but worth a hit anyway. You could be right about it being inadvertently made that way, but I've got 2 old spare back plates, and they too have these marks/ridges, although to a lesser extent.

I'm thinking it's wear, that only shows up after a very long time in use, with multiple cycles of adjusting wearing out brake shoes, which over 45 years I have done a lot. Another thought occurs. Those cases where sometimes the thread strips in the backplate, often caused by lack of grease/rust, but perhaps aided by a stuck wedge pushing back against the thread. Anyway, I just thought it interesting enough, to add it to the bbs archives, in case eventually it happens to someone else, and hey presto, -- I got there first. 🤣 Although, working on the principle there's now't new under the sun, I bet it has happened to someone else, who either never mentioned it, or never worked it out. |

| anamnesis |

| I am sure it must happen to others but the ridge looks pretty inconspicuous in your photos and I guess most wouldnt spot it as you did. Well done!

The " light tap with a heavy hammer" is a colloquialism. It means a pretty firm bash which should deflect the arch of metal in a bit despite its thickness. Too much though and it would jam the wedge anyway. A while ago there was a shortage of good backplates and useable second hand ones became expensive hens'teeth. Invariably the problem was worn or stripped threads in the adjuster boss in the plate. Other than it being a fine thread it is an easy job to drill out and replace it with a new boss. It can even be done in situ on the car from the front of the plate with just a couple of small tack welds. |

| GuyW |

| Yep, I had to zoom in and enlarge the image to get a picture of it. It's not much of a ridge at all, but still enough to jam the wedge against. I only found it because my wedge was jammed, and I was determined to find out why.

Ah right, smack the hell out of it. Lol. You're right about expensive backplates. 51 quid inc post,for a 'pre-owned', complete with rust, "VERY MINOR HOLE IN EDGE". Cheap as chips, which ain't cheap at all these days.😁 https://www.ebay.co.uk/itm/234209562669?hash=item3687fa502d:g:AnMAAOSwG7lhVICr |

| anamnesis |

| What it needs, is an enterprising company to make new improved versions. Maybe Front Line? What ya think Nigel? 😉 I don't much favour sunday drives anymore. Too much bloody traffic. It's quieter in the week. 😂 |

| anamnesis |

This thread was discussed between 07/04/2022 and 08/04/2022

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now