MG-Cars.info

MG Midget and Sprite Technical Rear Hub Gasket BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

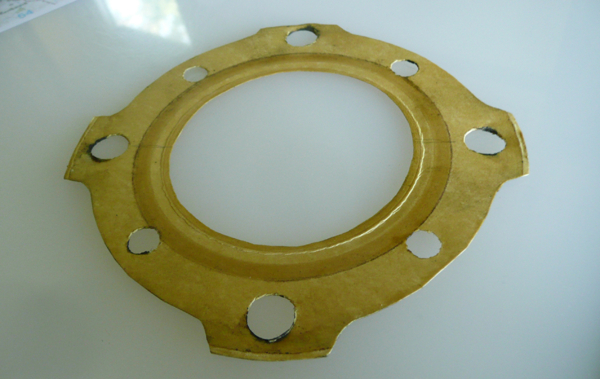

MG Midget and Sprite Technical - Rear Hub Gasket

| Can someone remind me what the decision is on whether the paper gasket should overlap the rubber O-ring? I remember some debate, and the one I've just taken off looks as if I might have trimmed the inside radius. Could account for the black oil everywhere. I haven't got a new one (lost it), so what's the nearest thing to gasket paper in a normal household? The old one is about 0.020". |

| Nick and Cherry Scoop |

| Yes, it should overlap. |

| Dave O'Neill 2 |

| Nick Malcolm Chevalier on this list and in your part of the world makes these gaskets in a range of thicknesses and sells them as a set, so you can use what suits. He has an eBay shop and Facebook page - Chavalier Classics. Recommended. Best wishes Mike |

| M Wood |

| Thanks very much. Mike. I haven't got time to get anything by post. I'm just contemplating various cereal and other packets. |

| Nick and Cherry Scoop |

| Cereal packets won't work as they're porous. I gave up using gaskets 10 years ago and now coat the O ring and halfshafts in silicon sealant. Once you've degreased and applied a smearing to both surfaces, tighten the joint using wheel nuts to normal torque followed by the half shaft screws - then leave overnight. You won't get any leaks this way. |

| f pollock |

| Thanks very much for the tip. My wife has come up with some stencil paper, which I might use, but sealant sounds good too. I won't be able to get silicon sealant now until Monday. Will either blue or red Hylomar do the job? |

| Nick and Cherry Scoop |

| Nick, Is this for the same car you showed in photos after shot blasting? If so, I don't understand the lack of time to get proper parts as it doesn't seem that you will be driving it this weekend anyway. Sounds like the old saying, "Never time to do it right; Always time to do it twice". Admittedly I've been guilty myself on more than one occasion. Charley |

| C R Huff |

| I don't think either blue or red Hylomar are silicone based sealants. I'd guess they're probably urethane based products which may get washed away in this situation. |

| f pollock |

| Charley I think that Nick mentioned in another thread that he was working on his Morris. I'm guessing that this is what he is referring to. Same rear hubs, though. |

| Dave O'Neill 2 |

| How about a good quality paper plate that has a "leakproof" coating on it? I have never tried this so it is only a suggestion. Remove the studs and place the "gasket material" over the holes. Use a clamp to hold it in position then place a ball peen hammer on the gasket over one of the stud holes round side down. Hit it with another hammer and the hole will be perfectly cut. Put a bolt in to hold it in position and repeat for the other holes. The inner and outer diameter cuts are not as critical. Good luck. |

| J Bubela |

| WSM lists the paper gasket as 0.010" thick. |

| GuyW |

| Well, it's done. I did use some stencil paper that Laura had - the stuff that crafty people use to cut out patterns for printing with sponges and so on, so it must be impervious.

Of course, when the hub was all done and bolted up, I was ready to re-assemble the brakes, so I went to the box of 7" shoes and there was a plastic bag with two hub gaskets in it. I expect I put it there thinking it would be an obvious place to look. Anyway, the new gaskets are 0.005 thick, and the stencil gaskets I have used are 0.015. Thanks to everybody for your help and advice. It's good to talk. |

| Nick and Cherry Scoop |

| I think I am right in saying that the reason the gasket thickness is critical is that the tightening of the assembly also clamps the outer race of the bearing to prevent it turning in the housing. If the gasket is over thick the bearing could spin and if it is too thin the clamping action leaves a gap through which oil can seep out. |

| Graeme Williams |

| Sorry, late to the party on this one, I hope you got sorted Nick. from my research I found 16 thou or 0.4mm was about standard thickness and generally worked well. But with a bit of wear you could go down to a 6 thou, or no gasket at all. What Graeme says is correct and it's a big flaw in the cheapo reproduction kits. The gaskets in them are way too thick, resulting in a gap between the shaft and the bearing which can allow the hub to move about. Regards, Malcolm |

| Malcolm Le Chevalier |

| Blimey. I did not know that. So, as you tighten the wheel nuts, the half-shaft endplate squashes the O-ring until metal-to-metal pressure is achieved between endplate and bearing case? So, is the bearing always 0.016" proud of the hub face, allowing a gasket to fit there? If gasket too thin, does the bearing get pushed further in, and does it mind? |

| Nick and Cherry Scoop |

| The bearing can't be pushed any further than the shoulder it sits on. |

| Dave O'Neill 2 |

| The bearing sits something like 8 - 10 thou proud. I don't know what the design figure is, this is what I have measured on a selection of hubs. A typical paper type gasket will compress approximately 50%, so a 16 thou (0.4mm) gasket will compress to around 8 thou resulting in no gap between half shaft and hub. If the gasket is too thin, the bearing is clamped, but you have reduced compression on your gasket and O-ring, so increased chance of leaks. Cheers, Malcolm |

| Malcolm Le Chevalier |

| Thanks, Dave. I get it now, and I see how the projection of the bearing could be accurate.

Well, I've taken the halfshaft out again and removed my new gasket, because I thought I might have cut it so that it would lap over the bearing. And I had, as you can see. The only parts of it that had been in proper contact with the hub are at the 0-ring and the bearing. I will now cut it so that it's clear of the bearing. After taking the gasket off, I did try measuring any offset between hub face and bearing, and blow me, it's something like 0.012". Good job, Malcolm!

|

| Nick and Cherry Scoop |

| THe WSM quotes 10 thou for the gasket. If the gasket is too thin the bearing holds the clamping force off the gasket and it leaks. I find whenever I remove the brake drums, the little countersunk screw clamping it all together fails in the task and a leak starts. Annoyingly these leaks can get onto he brake shoes and make them useless. That is a real problem if you don't take care pulling the half shaft |

| Graeme Williams |

| You could drill and tap a second screw fixing |

| GuyW |

| Just measured the gasket in the kit i have got ready to fit and its 25 thou |

| mark heyworth |

| Surely the main oil seal is the O-ring. As long as it's well squashed by the time the bearing is clamped, the role of the gasket is to fill the gap between the faces (gaps being by their nature bad) outside the O-ring. Worth measuring the bearing projection from the hub face, and then making a gasket to fit, using Malcolm's compression rate, I guess, but 25 thou sounds a bit thick. |

| Nick and Cherry Scoop |

| I also use bearing fit locktight. A bit belt and braces l admit! |

| GuyW |

| Good thread. I have learned a lot from it. Thank you. |

| Nick and Cherry Scoop |

| Yeah 25 thou sounds thick. Is it one of those orange colored plasticy carboard feeling gaskets? They are too thick and don't compress as much as paper gasket material either. I did measure the gap with one of them installed, but don't have the figures to hand. 0.4mm (16 thou) Flexoid works well. Malc. |

| Malcolm Le Chevalier |

| It seems to compress quite easily even just in the micrometer it goes down to 16thou without any trouble |

| mark heyworth |

| Purely in the interests of science, I have just measured some 'used' gaskets from my collection of hubs, and they come out at a shade over .011" I also measured the bearing face to hub face step on three hubs, and they were all about .011" also.

|

| Dave O'Neill 2 |

| just been sorting some things in the garage and found 2 spare gaskets from moss and they are 18 thou so will measure and use which ones are needed |

| mark heyworth |

| I thought I'd made a second post yesterday! I measured some NOS Unipart gaskets and they were .018" to .019"

|

| Dave O'Neill 2 |

| I have never quite understood the purpose and logic of the paper gasket, given that the rubber 0 ring should on its own provide the oil seal. I did understand that the half shaft domed end clamps the outer bearing, which stands proud of its housing in the hub. So,why the paper gasket at all?

I think Malcolm mentioned it earlier - the paper limits the clamping action so the rubber ring cannot be over squashed, and l guess that in extreme cases it can prevent overtightening and distortion of the outer bearing race. |

| GuyW |

| I think that the paper gasket may just spread the load so that the hub and half shaft flange are relatively fully supported around their adjoining faces. O ring sealing applications vary widely depending on the job being performed but I think in this application it is a static seal which doesn't see movement so can tolerate higher O ring distortion than a dynamic (sliding) seal. |

| David Billington |

| Ah that's interesting. Yes, l can understand the extra support being provided. In fact as the wheel studs are towards the outer margines of the hub, overtightening of wheel nuts if the paper gasket wasn't there could l suppose distort the half shaft end itself. Certainly it would add unnecessary stresses in that area. |

| GuyW |

| Just to throw something else into the mix, I have often postulated that too thicker gasket may be part of the reason why the half shafts break. If the bearing isn't properly clamped, the hub and half shaft can then move in and out of the axle ever so slightly. Resulting in the half shaft and diff splines moving and rubbing against each other in a way in which they were not designed to. Movement leads to wear and the wear contributes to the failures we see. Malc. |

| Malcolm Le Chevalier |

| The original A series axles did not have the O ring, just the gasket. They were modified around the late 50's I believe.I had an early series II Minor which di not have the O ring but a later 1961 Minor 1000 did. I think its all about reducing the oil leaks rather than anything else. |

| Bob Beaumont |

This thread was discussed between 15/07/2017 and 19/07/2017

MG Midget and Sprite Technical index

This thread is from the archives. Join the live MG Midget and Sprite Technical BBS now