MG-Cars.info

MG TD TF 1500 Mark in barrel BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Mark in barrel

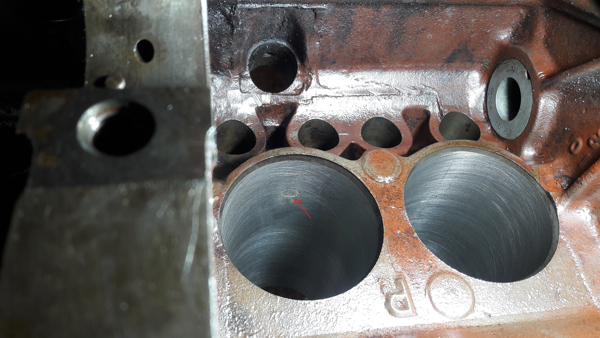

With my block back from being rebored on close inspection I found the "mark" in the bottom part of one of the barrel walls.I did not notice on dismantling. Anyone any idea. It's circular in shape and on enlarging the picture the outside of the "circle" is in the form of indentations rather as if made by a saw blade. I believe it wil be below the top rings. Not sure about the bottom one. The block was pressure tested and has been bored to 30 over. Before I discuss it with the engineering company I'd appreciate forum members views

|

| JK Mazgaj |

| Be easier to see if you cropped the original image and zoomed in, example below taken from imagine off site so may lack fine detail and size, you could do better with original image now you have these two images for perspective, and you can put two images per post. HTH. Sorry I've no real idea what that might be only a guess.

|

| Nigel Atkins |

Does this help

|

| JK Mazgaj |

| Did the block spend any time lying around on its side with the pistons in the bore. If so it could be a corrosion mark. ray |

| Ray Lee |

| just had a re-think, the diameter is too small to be gudgeon pin mark Ray TF2884 |

| Ray Lee |

| Your second photo is less 'zoomed-in' than the one I put up but you're getting the idea.

To have included that tiny red arrow your original image must have been quite 'large' so if you crop that original image and post here it should be a bigger image that will fill the (white) space available and be 'magnified' in on the circle (and arrow) both of which will appear larger and more detailed here. The images lifted from here are only up to a certain size so contain only so much details before you start to see the pixels a bit. I don't have any large images to hand but just as an example, original and cropped (and enlarged) from shown original. (I hope this makes sense I'm not the best at explaining myself nowadays.) -

|

| Nigel Atkins |

| Trying again. I'm afraid I know more about my MG than about computers Ha Ha. In actual size the circle is about 10-12mm in diameter as an estimate. At first I thought it was a "plug" in the barrel wall that had been honed/ground down but as stated on magnification of the photo the circular mark I liken to a scour made by a hacksaw.I will have to check tomorrow but I would add the marks made in the barrel wall made when rebored don't appear to continue through the "circle".

|

| JK Mazgaj |

| If you want to email me the original image as an attachment to the email, then provided it's a normal file and our respective email providers can handle it, I'll see if I can 'magnify' the mark with clarity. I'm no computer (or any other) expert though. |

| Nigel Atkins |

| For me, if I was doing that engine for a customer, I'd be putting a new sleeve in it.

It's been sleeved before so would be reasonably inexpensive --press it out press a new one in and rebore to match the rest--and forget about it But- Because it's been sleeved previously there would be original metal behind the sleeve so not much chance of water leaking which if they actually did a pressure test would prove that Bit of a strange mark though all the same, not from a gudgeon pin as that would be 90deg around, but being right down the bottom there it shouldn't be an issue as far as oil consumption or compression issues I'd be taking it back and make them prove to you it's good---make them magnaflux that area just to make sure it's solid and if ok run with it as is, but best option--new sleeve willy |

| William Revit |

| It would've been interesting to see the original cylinder wall before boring.

It "looks like" pitting corrosion as if a copper or stainless washer set there, damp, along the lines that Ray mentioned. If you had it rebored to .040" over, you'd only remove another 0.005" and you'd probably still see the circle. Two strokes run with large holes in the cylinder; these pits do not look deep enough to be of any significance, especially since they likely are below the compression rings. I wouldn't worry about it. |

| JIM N |

| Going by the first photo, it looks as if a hole has been drilled all the way through from the outside. It appears that the hole in the cylinder wall has then been plugged, probably from the inside. In that position, it should be possible to examine the outside of the cylinder wall to see if there is a short length of plug projecting. As the block has been pressure tested, either the drilling was below the water jacket, or the plug is water-tight. |

| R WILSON |

| OK so lengthy chat with two of the engineers at the machine shop who specialize in classic and race engines. Their view is that it is a original casting issue. In their opinion with no immediate water jacket and having been pressure tested see no problem with using it as is although as the client if I wanted it sleeved they let me think it over but emphasis its location should as stated cause no problem. They have seen it before and believe it to be caused by probably a "air bubble" in the original casting and due to its location remained un-noticed may even only been exposed when the 15 thou rebore look place (was standard). They felt that as below the rings and no water jacket in the immediate vicinity I shouldn't have anything to concern myself about. |

| JK Mazgaj |

| If they've had a good look and are happy with it- They're the ones that can actually do the touchy feely thing and as they say it's behind the lifter chest up at the top of the void behind the distributor drilling, so no coolant there I think I'd be taking them at their word and continue on willy |

| William Revit |

This thread was discussed between 16/05/2021 and 19/05/2021

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now