MG-Cars.info

MG TD TF 1500 Modern 6-vane impeller feasibility study? BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Modern 6-vane impeller feasibility study?

| GK Guenter posted the engineering diagram of a modern 6 vane impeller design here a while back, I thought I would repost it with the following question: Does anyone here on the forum have the skills to turn this into a CAD file? If so, it could be the start of a project to produce a few of these for member's testing... Any interest out there? I don't have the CAD skills, but with all the engineers out there on this forum, maybe someone would like to take this on... Once a readable CNC file, we could get pricing on how much to do a short run...

|

| Geoffrey M Baker |

| Geoffrey, That is a CAD drawing. It is very easy to redraw it but why not ask GK Guenter if he would mind and then, if he agrees, ask him to send it to you in dxf (Vector graphic)Format. I'm sure he would oblige if you offer him an impeller. Regards Declan |

| D Burns |

| Declan, I think he just found this as an image file, not the original CAD drawing. But I'll contact him... thanks! |

| Geoffrey M Baker |

| Has anyone determined if more vanes really increase the cooling capacity of our systems? There are a lot of variables. Presumably, the factory did some testing. I would like to see a dyno test at 3 different rpms with 4, then six vanes, then another with different pulley sizes. While we were at it we could try the same test with the plastic MGB fan and again with a 15 inch electric fan. Some of you guys in Arizona probably have a pretty good idea of what works and what doesn't. My limited testing shows an improvement at low speed with the MGB fan on my TD. |

| cj schmit |

| I have a guy who can do the dyno tests for me, but the first step is to build this. The current 6 vane impeller is reportedly an improvement, but this one should be considerably more efficient as the existing one is a very primitive cast with a simpler design. |

| Geoffrey M Baker |

| I have been able to find a hires pdf file of this image and convert it to .dxf which should be a CAD readable file. I'll talk to some CNC shops here and see if they can read it. The first one wants an .igs file but I can't find a way to convert it to that format... |

| Geoffrey M Baker |

| Geoffrey, the 6 vane is already out there. A fellow in the home land is making some and it may be the source of the ones sold close to you. I put one in a TC last year and was very pleased with what we received. http://www.fromtheframeup.com/uploads/Cat_11_CS.pdf |

| MG LaVerne |

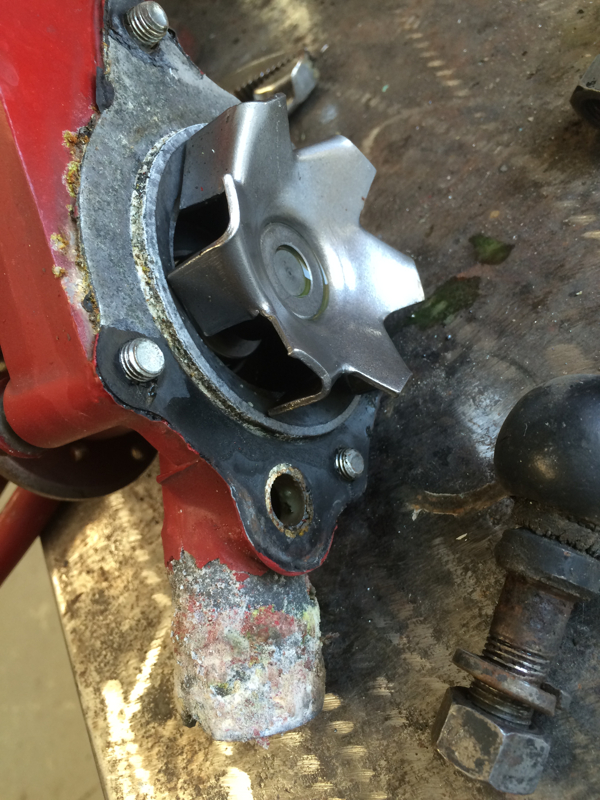

Laverne, there is a six vane impeller on the market, but it is, I believe, a much inferior and primitive design. Do you have a picture of one? The ones I've seen all look like this:

|

| Geoffrey M Baker |

| I've sent email to fromtheframeup.com asking for a photo of their impeller. I'll let you know what he says... |

| Geoffrey M Baker |

| When I last lived in Southern California I worked on a very un-cared-for TD that overheated badly, even under normal street driving, so I cleaned out the block, and put on a new MOWOG water pump (available back then). I reamed out the one plugged hole in the front water passage and drilled a new hole at the rear, and replaced the core plugs. I flushed the radiator out upside down, and that car NEVER again had an overheating problem, not even on the hottest of days, slowest traffic and longest of up-hill runs. It might have had a radiator with one more row of tubing, and I also remember finding a number of pieces of left-over steel rod in the engine, used as support in the casting process, that certainly upset the coolant flow through the engine. My real point is that, to my way of thinking, a cleaned-out system with a good distributor and correct timing should not overheat, and needing much more than the stock system is just ignoring a different problem. Very often overheating problems are connected to badly worn or sticking advance units in the distributor. Tom Lange MGT Repair |

| t lange |

| I would not disagree, Tom. I've just finished rebuilding the radiator to it's original condition (or nearly) and have had the block magnafluxed. The rear hole looks good, the guy is going to look for the front hole and drill it if necessary. When I'm done, I don't expect to have overheating. On the other hand, people have reported good things about 6 vane impellers, so if it's practical to find or make a good modern one, it cannot hurt, either. |

| Geoffrey M Baker |

| I agree with Tom. |

| mog |

| From the Frame Up does not sell impellers individually, only as part of their upgraded water pump. |

| Geoffrey M Baker |

| Geoffrey, I can have my designer do it in Solid Works in the morning if that will work. Are you thinking cutting or 3D printing? Bill TD24570 |

| Bill Brown |

| I was thinking we could go either way. I can't get a price on a CNC job without a computer file. 3D printing I'm sure is cheaper but I haven't looked into the issue of materials; can they print it in a material durable enough for this use? Bill, I have a much higher quality pdf file and have converted it to a dxf file as well (not sure how much of it will be useable though) so if you want those give me your email... |

| Geoffrey M Baker |

| No pictures Geoffrey but scroll down quite a ways on this link. I believe the impeller was much like the Racemetal one. I just removed a water pump from an MGB with a stamped steel impeller...ya want ta have a go with it? http://ttypes.org/ttt2/?s=water+pump&submit=Search

|

| MG LaVerne |

| Interesting, Laverne! Looks like the MGB impeller might be a close fit, if you want to, send it along and I'll check it out! The article you show is interesting as well but I'm not sure that impeller would work (it's for a TA with quite a different housing). I'll keep looking for a decent 6 vane impeller on the market... and I'll keep thinking about the feasibility of bring the Jaeber design into reality.. |

| Geoffrey M Baker |

| Geoffrey, my cad guy will look at it in the morning and let me know. It should be simple to do. He just has to model one vane and replicate it six places. It should be a fairly small file I can email it to you. I will most likely be asking your email address where I can send it to. Bill TD24570 |

| Bill Brown |

| Geoffreybaker@cox.net |

| Geoffrey M Baker |

| Geoffrey, you have mail Bill TD24570 |

| Bill Brown |

| Thanks very much, Bill; I've forwarded it to a CNC shop and will post back with the response. In the meantime, here is a screenshot of Bill's pdf file to show the impeller in 3D.

|

| Geoffrey M Baker |

| The steel impeller La Verne posted is a terrible design. Cheap aftermarket aluminum MGB water pumps came with them for years, and the inferior cooling ability soon became apparent. Most shops have tossed piles of them in the garbage and reinstalled the cast iron version as original. The difference is plus or minus 15F at highway speeds. I fully agree with Tom, the cooling system is more than adequate for the small T-Series engine. Just look at the size of the radiator compared to the engine. In some older cars there was no water pump at all, just thermo-siphon, and they cooled just fine. Moving more water will not necessarily improve cooling. The water needs to spend a specific amount of time in the radiator to achieve optimum cooling. Running it too fast will have a detrimental effect. What that flow rate is, I don't know. All I do know is that everyone I know with the currently offered bronze impeller and an otherwise standard system in good order suffers no cooling problems. More power to whoever comes up with an even better one, but I'm not convinced it's worth the effort or expense. In my view, it's a cure for a problem that doesn't exist. CJ, a more efficient fan design will certainly improve cooling at low speeds in very hot climates. At speed or in cooler climates it will not do anything except make more noise, and perhaps rob an extra 1HP from the engine. Couldn't hurt anything though. Some people run MGB fans or modern flex fans with good results. |

| Steve Simmons |

I hate to tell you guys the design is not new. See the attached drawing from July of 1954 from Morris Motors engine branch.

|

| R Taras |

| Here's a good website on centrifugal water pumps: http://www.hemmings.com/hcc/stories/2007/06/01/hmn_feature19.html And this: http://hydra-tech.com/9-different-impeller-types/ Regards Declan |

| D Burns |

| geoff, As long as you are going through the trouble of having one made, wouldn't it be sensable to curve the impeller blades a bit??? rather than being flat?? It sure would help the flow... Steve |

| Steve Wincze |

| Steve Simmons is correct when saying water need more time in the cooling phase. We learned that when racing many years ago and actually cut impellers down and enlarged pulleys to slow the speed of water through the systems. The slower the water runs through the radiator, the cooler it will be when it gets to the exit point. Most cooling problems, notice I said MOST, stem from a plugged system, be it in the block and/or radiator, then comes timing and lean fuel mixtures. Most 50/60 year old blocks will be loaded with crud and cakes of rust which must be removed and hot caustic tank will help quite a bit, but running circular wire brushes through the block will get what's left. JMHO & experience. PJ |

| Paul S Jennings |

| I believe both Paul and Steve Simmons are correct. I remember years ago when I was helping a fellow out in sprint car racing, by simply removing the thermostat out of a 302 Chevy engine, it would overheat. We had baffles with different sized holes to replace the thermostat depending on the track and the engine heat. The coolant can move so fast through the engine, it will not absorb the heat and run hot. Bill TD24570 |

| Bill Brown |

| Bill, Paul, Steve, I have no doubt you are absolutely correct in your statements that "coolant can move too fast through an engine" thus reducing efficiency rather than improving it. Especially in racing situations where they would naturally try to achieve the maximum, obviously, there is a point beyond which you achieve a negative result. My point, in a TD engine, we ain't there yet, folks. As everyone, without exception, has stated that a six vane impeller is an improvement, cooling wise, on a 4 vane, in our cars, obviously, using a six vane impeller does NOT take us over that edge where we start to lose rather than gain efficiency. The question of whether a modernized six vane impeller with improved characteristics and better flow, would be more, or less efficient than the current primitive six vane impeller, has not been answered. I do not believe it will take us over the edge... I believe we aren't really that close to that edge quite yet. But if it does, gentlemen, I will report it to you... Fair enough? |

| Geoffrey M Baker |

| An update: while CNC machining is going to be way too costly, it looks like 3D printing in steel is a real possibility. Apparently the process lays down steel powder and glue, and once assembled some kind of infusion process replaces the glue with bronze, leaving a strong, durable metal. I'm hoping to improve on the design a bit by curving the blades, and then I'll order one next week and when it arrives I'll report on it. I'm going to build a test bed to test the water flow rates, and will report once I've tested both the 4 vane and the new design 6 vane. If anyone has one of the 6 vane impellers currently on the market and wants to send it to me I will include it in the test so we will have flow rates for all 3 units (I'll mail it back, honest I will :)) The steel solid material has the following characteristics: Alloy Family: 420 SS+ Bronze (40% bronze) UTS: 99 KSI (682 MPa) Yield: 66 KSI (455 MPa) Modulus: 21.4 MPSI (147 GPa) Elongation: 2.30% Hardness: 20-25 HRc The material is heat resistant to 831ºC / 1528ºF degrees. Expect a price in the $100 range. |

| Geoffrey M Baker |

| Stock water pump, original radiator, temp 105f, 2 1/2 hrs bumper to bumper traffic on the" expressway" near Chicago. No cooling issues. I think if you are having issues an upgrade to the plastic mob fan might give you more bang for your buck while stuck in traffic. Nothing in period literature or forum history of properly tuned TD cars boiling out coolant. Regards, tom |

| tm peterson |

| *should read 1 1/2hrs in rush hour bumper to bumper traffic. TP |

| tm peterson |

| Tom, I'm going forward with this project for two reasons: firstly, at around $100, this will be one of the two most inexpensive improvements that can be made to a cooling system. (The other, as you say, is an MGB fan, which retails at $80). One advantage of the impeller is that it is invisible, and won't change the look of the engine compartment, so for purists and concourse people, that should be a definite advantage. I don't disagree with all those advocating other choices including the most expensive - pulling the engine and cleaning the block - or recoring the radiator, or adding an electric fan (requiring an upgrade to your generator). But if you're having overheating issues, and are on a tight budget, this may be the best short term bang for your buck. I plan on doing both water flow and temperature testing, to compare the new impeller with the old 4 vane and the old six vane (again, if anyone has a six vane they can loan me, please let me know, it will give us good data and I will return it after testing). Once that is done, people can decide for themselves which is the most worthwhile investment they want to make. I would also certainly never suggest that a six vane impeller is a replacement for making sure your block is clean and your radiator in top shape; of course every owner needs to make sure their systems are running optimally. But in hot climates (like mine) the six vane impeller may well turn out to be an inexpensive improvement that helps keep your engine running smoothly in the right temperature zone... And who knows, if enough people are interested and purchase the 3D printed version, it would indicate an interest sufficient to invest in a production run, which could drop the price significantly, perhaps down to $30 or $40... at which point it might definitely be the best bang for your cooling buck. I will continue to report progress. I expect to have a finished design early next week and will put in an order for a 3D printed steel/bronze test unit. |

| Geoffrey M Baker |

| I don't have one on my TF, but I am a fan, no pun intended, for the MGB fan and have thought of one for the TF, but with a clean block and new extra core radiator, I'm hoping I won't need one. I'll find out on one of our, not to rare, 100 degree August days. PJ |

| Paul S Jennings |

Paul, I have one on Lazarus, my TD. Only reason is for the annual 2+ hours inching along, into the noontime sun on the Fourth of July. Handled that fine last year. No more looking at the water temperature needle in the oil pressure numbers. Bud

|

| Bud Krueger |

| Thanks to Bill Brown for assistance with converting to a readable computer file! Once created as a step file, I was able to convert it via sketchup to a 3D printer readable file (.dae). The impeller now exists in the digital world. I have uploaded the file to shapeways.com and ordered a 3D printed version in bronze/steel, which I should get in about two or three weeks. You can view the impeller here: http://shpws.me/Hm4T It costs $110 to do this in 3D printed steel. I have no idea yet how durable this material is; this is being done for testing purposes only. However, anyone who wishes to is free to buy one themselves for their own testing. Good luck and have fun! I will report when I get the impeller and am able to begin testing it. I hope, as I said earlier, to report back with flow rates initially, and later with engine temperature measurements. Here's a picture! Once again, thanks to all those who have made suggestions and helped out in the process of making this into a reality... it's been a very fun project and who knows where it will go!

|

| Geoffrey M Baker |

| Have fun Geoff - very impressive. |

| mog |

| Geoff, can (will) you provide your 3D model for the public? I would like to try to make an CNC machined brass or bronce part. Cheers, Guenter |

| GK Guenter |

| Guenter, I priced CNC machining at $550 each... |

| Geoffrey M Baker |

| Nice work! Look forward to the results. |

| Frank Cronin |

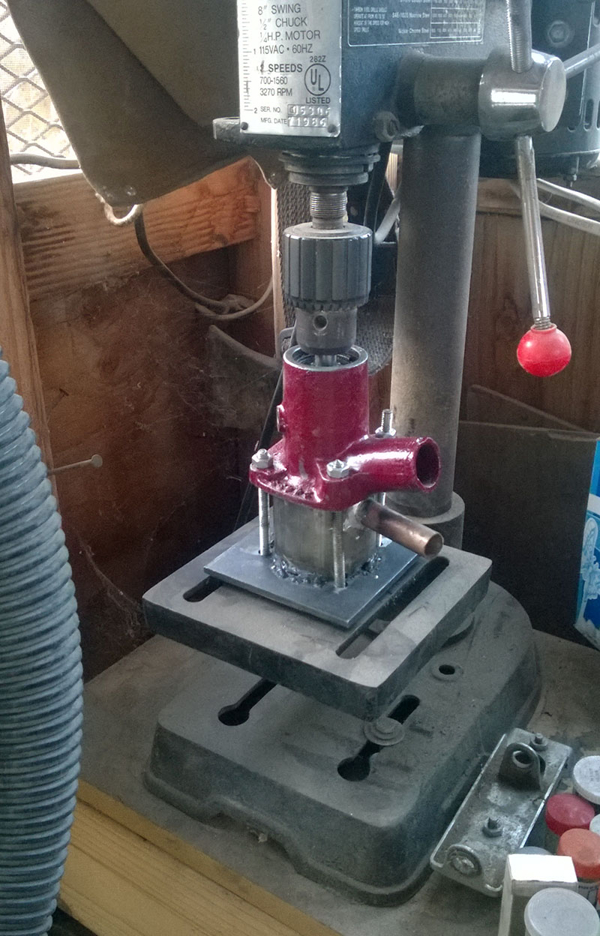

| I was able to borrow a standard six vane impeller, which arrived in the mail yesterday. I now have a 4 vane and a standard 6 vane and am waiting on delivery of the improved 3D printed 6 vane impeller, which may take two weeks. I have built a test bed which mounts in my drill press and should give consistent readings at 1350 rpm. I will finish setting up the system including tanks, hopefully in the next couple of days. When the 3D 6vane impeller arrives, I should be able to determine flow rates for all 3 and will publish the results. Later, once my engine is back in and running, I hope to take some engine block temperature readings with all 3 as well. This continues to be a fun project and I hope it results in some good data being made available to everyone on this forum! The results should be an extremely accurate measurement of how the impellers do in relation to each other, i.e. percentage increase in water flow, between each impeller. However, please understand that the flow ratesI publish won't reflect actual flow rates in your engine; because my test bed constrains the water flow inside a half inch pipe, which is much more restrictive than the engine opening on your TD/TF. Here's a picture of the test bed, which is just a section of 2.5 inch pipe welded off on one end with a half inch pipe mounted to channel the outward flow of the impeller, bolted to the water pump. It may leak some - but it will leak equally with each impeller :)

|

| Geoffrey M Baker |

| Geof, I'm impressed with your tenacity. Here's 2 cents worth- you'd expect 4 to 6 vanes to be better than one single vane, but if you had 100 vanes, would that be higher flow or way too much restriction between the vanes? Four vanes move four larger volumes of water per revolution but six vanes obviously move six smaller cubic inches of water. It should be interesting to see your results. |

| JRN JIM |

| JRN, We've already established (by common consensus on this forum, by testing in the real world) that 6 vane impellers do a better job than 4 vane. That's a given. Now will a modern 6 vane impeller, with thinner blades, a better "rake" and a curved design improve on this? It's hard to imagine that it would not... I look forward to publishing the results. I have hit a snag, though... I need to reverse the direction of my drill press! I'll have to think on this :) |

| Geoffrey M Baker |

| Geoff, Getting the drill to turn in reverse is not impossible, but quite impractical. I had to do it a few years ago to remove a bearing. The trick is to cross the belts on the sheaves. You will immediately realize the impracticality as the belt will DEFINITELY rub at the cross-over point. To do mine, I took a piece of thin rope and measured the length with it in the crossover position. I went and bought two belts that might work. I backed off the motor and removed the regular belt and installed the first of the two belts, crossing in the middle. I then tightened up on the motor. I didn't need the second belt. I then secured a thin rub-plate, made of tinplate between the belt surfaces at the cross-over point to minimize wear. I had to jury-rig a crude, but temporary mounting, but it worked; and just long enough for me to get the job done. Not pretty, but it worked without having a fire! Gord Clark Rockburn, Qué. |

| Gord Clark |

| Geoff, why not use a 1/2" reversible electric drill? |

| R Taras |

| Butch, I was thinking about that but the drill I have is variable speed and pretty wonky and I'm afraid that I would not be able to keep it at the same rpm for each impeller, which would be a serious flaw in the comparison. I think I can just take the motor off the press and mount it on the table, and put the pulley on the water pump and mount that on the table too, and connect with a belt. A bit more work, but not too hard to do. Apparently, you can reverse wire an AC motor in many instances... just not with my cheap drill press :(. I disassembled the motor and while it might have been possible to cut and rewire, I just didn't have any room in the motor housing to do it safely and get it back together without the possibility of shorting or the wires getting loose and touching the moving armature... I looked at crossing the belt, and could actually do it, but I'm definitely thinking the belt might melt before I finished the tests! So today, I'll see about setting an adjustable jig up on the outside table using the drill press motor, which comes off with three bolts. Thanks for the suggestions! |

| Geoffrey M Baker |

| what for? |

| mog |

| now you've lost me, mog...? |

| Geoffrey M Baker |

| why do you need to reverse the drill direction |

| mog |

| The impeller pumps one way; while the 4 vane blades are straight and perpendicular to the shaft, and would probably work either way, both six vane models are angled in relation to the shaft, and if turning clockwise will be much more inefficient than if turning anticlockwise. |

| Geoffrey M Baker |

| Is it just as a test rig? I was wondering if you where trying to machine something, sorry. in that case I would worry about side thrust on the drill head. You might be better with a simple hoover motor, pulley vbelt setup on a bench, old hoover motors/lathe motors are cheap as chips on ebay etc. |

| mog |

| Yes, this is just to do comparison testing on water flow between the three impellers. |

| Geoffrey M Baker |

| Just buy a small electric motor, and wire it up any way you like. Craig's List, $10. |

| Steve Simmons |

| No need...just used my drill press motor no problem. |

| Geoffrey M Baker |

This thread was discussed between 15/04/2015 and 25/04/2015

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now