MG-Cars.info

MG TD TF 1500 Pulling the camshaft - 51TD BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Pulling the camshaft - 51TD

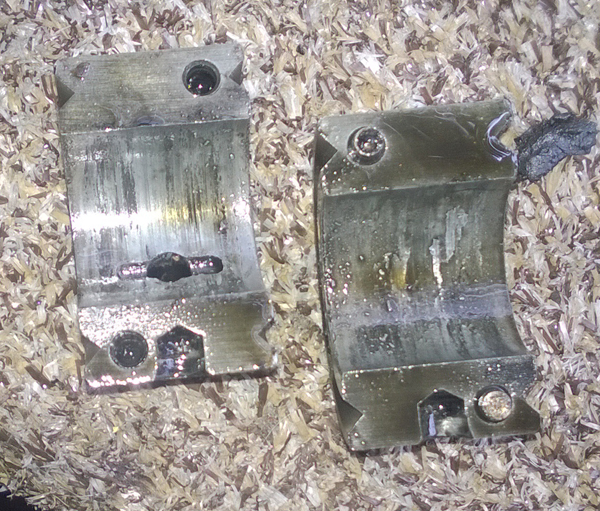

| Following up the thread entitled "51TD engine failure" we have determined it is the camshaft that was locking up the engine. I have been able to pull the camshaft mostly out of the engine. The culprit looks like the cam center bearing - see photo. I cannot, however, remove the camshaft fully; the rear bearing does not appear to fit through the front bushing. Possible reasons: damage to the rear bearing OR it is oversize. How do I remove an oversize bearing from the camshaft while it is still in the engine??

|

| Geoffrey M Baker |

| The rear bearing should slide off the end of the cam. In most cases it stays in the engine block when the cam is removed. Hugh |

| H.D. Pite |

| HHuummm,, how about gentle use of a "slap hammer" on the cam????? SPW |

| Steve Wincze |

| Not pretty...too bad. |

| MG LaVerne |

| Hugh, all I can say is that this bearing does not want to come off the camshaft for whatever reason. Other than that, I can report that the camshaft appears to have no damage, even on the center bearing surface, it is unscored. So, back to the question of how to get it off... Is the rear bearing meant to pass through the front bearing bushing or is it too big in all cases? |

| Geoffrey M Baker |

| The bearing is too big to come out the front. Need to remove from cam. Perhaps put it back into the block, lock back with lock bolt, then tap the cam out. If it is scored like the center one, perhaps both were put in with the dowel pin in the oil feed? George |

| George Butz |

| I removed the rear bearing using a long rod and tapping it while holding the crankshaft and it came off pretty easily. It's not in good shape either but the good news is the camshaft looks absolutely pristine, no scratches or gouges on any bearing surface. So how do I remove the front cam bearing from the engine block? |

| Geoffrey M Baker |

| Here's a photo of the camshaft. I'll need to mike it but it is within profile, would there be a problem reusing it?

|

| Geoffrey M Baker |

| The front cam bearing is one that a machine shop will have to replace, if it needs to be. It's hard to install it without distortion, and is made oversize so it needs to be cut down to size to fit properly. I confess I am till having trouble believing that a cam binding up would be able to stop the engine from turning; perhaps the center bearing was installed with the oil hole off center, got no lubrication, and melted the bearing. But it's still a lot of force needed to prevent the engine from turning. If the lobes are about the same size and there is no galling of the lobes, it should be fine. Tom Lange MGT Repair |

| t lange |

| Tom, I should say that when the engine cut out, I was able to turn it over, but only about half a turn at a time using the starter motor. It would then stop. Once I removed the timing chain, the crankshaft turned over easily, and visual inspection of all bearing surfaces shows no damage to the crankshaft. The camshaft could be turned by using a spanner on the end nut, but it was pretty rough. The center bearing certainly looks to be the culprit, and very possibly was incorrectly installed. Regarding the front cam bearing, I've read several threads where people have discussed installing it themselves. I'm trying to figure out if this can all be done with the engine in place, which leaves me the following questions: 1) How to remove the front cam bearing 2) How to reinstall a rear cam bearing (can I slide the camshaft in, tap the bearing onto it and then slide it through and fit it into the rear?) Or do I absolutely, positively have to remove the engine to do this?? |

| Geoffrey M Baker |

| Another slightly different question: most of the tappets are slightly pitted on the bottom from contact with the lobes. Can I simply put these in a lathe and machine them flat again and will they be usable, as long as the tappet adjusters compensate for the couple thousands of an inch of metal that have been removed? |

| Geoffrey M Baker |

| Geoffrey, The cam photo ,looks very good but a good machine shop can measure the surface roughness and even polish the journals and lobes without changing the dimensions measurably. If the tappets show no pitting they can be reused. The surface hardening is not very thick and can be machined away easily shortening the life of the tappets very badly. I would go for new if they show wear. Regards, Jim Haskins 1953 TD |

| J. M. Haskins |

| I agree with Jim on the tappets. The centre & front bearings can be replaced with the engine in the car. Not sure about the rear. While the cam is out check the location of the oil feed hole in the centre bearing & gallery & familiarize yourself with the correct orientation. This is detailed in the thread "Replacing the camshaft" in the archive. Don't forget the circlip at the rear of the cam, which you shouldn't have to remove anyway. It's there to prevent you knocking out the rear engine plug on reassembly. Are you able to get the engine re-builder to defray some of the cost? Cheers Peter TD 5801 |

| P Hehir |

| Geoffrey, Back when I was young and dumb I replaced the front cam bearing myself...used a brake hone to enlarge it just enough to slide the front cam lobe in. Worked fine and the engine ran well. Genw |

| Gene Gillam |

| A couple of thoughts - the brake hone to adjust the front cam bearing sounds good, but may clog up the cam bearing. Cutting is really the best way. I cut a groove in an old camshaft, and use that to cut the front bearing to size - crude, but it works. Geoffrey - if there is ANY pitting on the tappets, they must be re-done. I have had great success with Delta Cams (there are many others), who re-surface them all the time, for just a few dollars each ($5?). I would not try to do it yourself, as the tappets are R54 hardness, at least, and they need to be ground to a 41" radius (if I remember right). It is certainly possible to fit new center and rear cam bearings with the engine in place; it's just awfully awkward. Be sure to trial-fit the bearings, as they usually oversize and need hand fitting. They should slide in, not need to be tapped in. Also, be sure the tappets rotate freely into the block - if not, it is a recipe for early tappet failure. The front cam bearing is a thin-wall bearing, very prone to distort on installation. I once made up a mandrel for installation, but prefer my machine shop to do it. Tom Lange MGT Repair |

| t lange |

| Replace the rod and pinch bolts with some of Tom's ARP bolts while it is apart. George |

| George Butz |

| Peter, I think the engine was probably rebuilt twenty years ago or more, and I have no idea who did it! Tom, guess I'll buy new tappets then... Still not sure about the front cam bearing, whether to pull the block and take it in. As they are available for $20, I'm tempted to try doing it myself and making a mandrel to fit... Gene, I'm old and dumb... I may try it... |

| Geoffrey M Baker |

| Geoffrey - I know you are confident you have found the problem, but I'm still struggling to identify what about the camshaft system caused the engine to stop turning in both directions, after a half revolution. A bad center bearing would not, because the cam bearing surface should be the same 360 degrees. I still can't wrap my mind around it, especially since you identified a clicking sound. Tom Lange MGT Repair. |

| t lange |

| Geoffrey - I am recommending you have your tappets re-done, not replacing them. Delta Cam. On a 30-year-old engine rebuild, I would check everything. The last engine I rebuilt had an SAE bolt forced in instead of a metric pinch bolt, and it was too long so the DPO's mechanic used 4 lock-washers to space it out... Check the oil pump cover, the rocker shaft and rockers, etc. for wear, as these all contribute to a decrease in oil pressure. Tom Lange MGT Repair |

| t lange |

| Geoffrey, I tend to agree with Tom. I would think for the camshaft to kill the engine, there would have to be a tremendous amount of galling on both the camshaft bearing surface and bearings. I would check and recheck everything in the cam drive system. Bill, TD24570 |

| Bill Brown |

| I agree totally with Tom Lange. Delta does nice work, they're fast and they are reasonably priced. I would probably send them the cam *and* the lifters ... have them re-profile the lifters, check the cam for correct profile, polish the bearing journals and then re-parkerize the cam lobes so that it breaks in nicely when you reinstall it. It won't cost much, but it's really the right way to go. |

| kmclemore |

| Another good one is Berry Cam in Minnesota. they have done many of them for our club. They do not do the hardening though. |

| T Maine |

| If the rear bearing was locked onto the cam journal then it may have been rotating in the block, and jamming against its locking screw. That "could" be the clicking you were hearing. Check for damage to the rear bearing locating hole and/or locking screw. If they are original lifters then they are chill hardened, in which case I suggest having them re-hardened after machining. The hardening isn't very thick. I would have the cam tapered and the lifters domed to encourage spinning and therefore extend life, but it isn't mandatory. You can replace the front cam bearing yourself if you have a tool to fit. The cam bearings that have to be filed down are to be avoided. Order one from Moss, they have the correct bearing and they go in without fuss. You probably won't have to ream it to fit but if you do, use an actual reamer, not a hone. You don't want abrasive material left in the white metal. If you don't have a tool with a PRECISE fit then either get one or leave it to a machinist. I mentioned oil starvation from installing the center and rear bearings incorrectly in your previous thread, but note that the front bearing also has a hole that needs to be lined up. And don't forget to tab it in place. Ream after bending the tab, not before. Good luck! |

| Steve S |

My cam reamer. Works great on tabbed front bearings. Bud

|

| Bud Krueger |

| Geof, Take a couple minutes and familiarize yourself on the subject of cams/followers for our MGs. Supplemental Notes from Moss Motors... http://www.mossmotors.com/graphics/products/PDF/451-260.pdf http://www.mossmotors.com/graphics/products/PDF/433-365.pdf While your camshaft is out, post indentifying numbers or marks to help figure out what cam you have. You'd hate to think someone slipped a new cam in with the the used, incorrect lifters. Now's the time to check it. How about a photo of the problemchild and bearing remnants? |

| JRN JIM |

| Jim, I posted photos of the center bearing and also of the cam in this thread already. If you want to see anything else let me know and I'll take a picture. To remove the front bearing, should I just lever it out with a screwdriver? At this point I'm leaning towards pulling the block and having a machine shop reinsert new bearings. I'll be taking the cam to them to spec it and see if it is usable. |

| Geoffrey M Baker |

| I've found it easiest to use either a socket or a piece of pipe that matches the OD of the bearing, and punch it through. Bend the tab up first of course. It should come out with several taps of a hammer. |

| Steve S |

| Geof, Before you open up a really nasty can of worms, look at the front bearing to see if it is obviously damaged; slip the front cam journal in the bearing to evaluate the clearance. If it ain't broke.... I asked the local machine shop here and they don't line-ream or line-bore bearings like that- and Jack Roush sends them work! JIM |

| JRN JIM |

This thread was discussed between 18/03/2015 and 19/03/2015

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now