MG-Cars.info

MG TD TF 1500 TD transmission mounting BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - TD transmission mounting

| In preparation of stuffing my engine in the TD I put the trans in today. I have run into several issues. 1)The new rubber blocks don't seem to want to compress so that I can start the clevis nut to the mount. 2) The driveline cant be bolted to the trans as there is insufficient clearance with the driveline tunnel at the leading edge 3)Does the slip yoke bolt to the trans or the pinion? 4)My trans tunnel flange is under the floorboards and seems to be correctly configured as the tunnel bolts to the package tray cross member correctly. So whats going on? What am I missing? Regards Bill Chasser Jr TD4834 |

| W. A. Chasser Jr |

1)The new rubber blocks don't seem to want to compress so that I can start the clevis nut to the mount. -I have used a bottle jack and blocks of wood to compress the transmission into the rubber enough to start the nut. Place the jack between the transmission and the frame loup that goes through the tub. 2) The driveline cant be bolted to the trans as there is insufficient clearance with the driveline tunnel at the leading edge -with the transmission, the rear axle, the driveshaft and the tunnel all bolted in, all should fit. 3)Does the slip yoke bolt to the trans or the pinion? -the slip yoke goes on the transmission end. David |

| D. Sander |

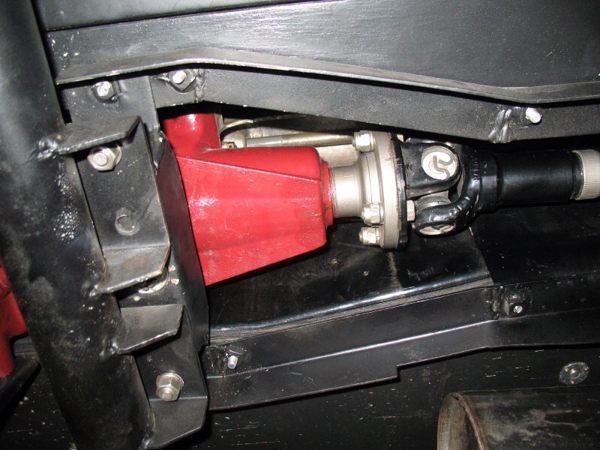

Sometimes a picture is worth a thousand words...

|

| D. Sander |

| Hi Dave I have the driveline in correctly but it will not bolt to the transmission flange as the slip joint is hitting the driveline tunnel before it will engage the flange. Also even if I could bolt it in place the zerk fitting will chop up the tunnel. The rubber is from Moss. I'm wondering if I need to shave the rubber blocks on a belt sander so the trans will drop down some. I hate to put a lot of pressure on the blocks to start the nut on the clevis as I don't want to break the tail housing casting |

| W. A. Chasser Jr |

| Recient posts have mentioned the Moss rubber needing to be trimmed. I always buy rubber products from Abingdon Spares. If the transmission is not snug in the cradle, it will be too high, which is probably your problem with clearence. David |

| D. Sander |

| Bill - I recently had the same problem fitting the rubber rear mount onto my TF gearbox. Here the thread of my questions and answers in the archives: http://www2.mg-cars.org.uk/cgi-bin/gen5?runprog=mgbbs&access=&mode=archiveth&subject=8&subjectar=8&thread=2015030703023024447 Based on recommendations from the board, I bought rubber mounts from Abingdon Spares and did not use my Moss mounts. However, I believe that you can tweak your Moss mounts to fit. 1) RUBBER BLOCKS - Grind the corners of the rubber blocks so that do not contact the rounded inside corners of the mounting bracket. Not just the bottom corners, but the ends also. This will allow the mounts to sit at least 1/8" deeper into the mount. I used my bench grinder. It takes rubber off FAST, so use a light touch. Also throws rubber dust everywhere. I smeared a little grease on the rubber and bracket to make sure that the rubber seats fully into the bracket. 1a) REBOUND RUBBER - I feel that the Moss rebound rubber "button" is too thick. The center fits into the hole in the mounting bracket. You will see that the edge of bumper hits the rounded portion of the indention in the bracket. I think that you can grind that sharp edge to better fit the bracket and allow it to sit deeper into the indention. If it is still too thick, then you may need to make it thinner, also. See image below. 1c) CLAMPS - I tried to compress the rubber with Quick Grip clamps on the gearbox and mounting bracket. Later switched to bar clamps which were stronger. They may have compressed 1/16" ... I dunno. It may have been just enough to attach the nut. 2) PROPSHAFT U-JOINTS AND TUNNEL - Now you have made me nervous. I noticed that the front of my propshaft tunnel is close to the U-joint. The car is still on jack stands. I'll spin the shaft tomorrow and see if it too close to the tunnel. The shaft will rise up a little when I lower the car to the ground because the stands are under the frame instead of under the diff and A-arms. I didn't put any spacers under the tunnel. Hope that I don't need to remove my newly installed floorboards and shim the tunnel. GRRRRR Luckily I haven't installed carpet yet. 3) SLIP YOKE - As David stated, the slip yoke is at the gearbox. 4) TUNNEL LOCATION - Yes, the flange of the propshaft tunnel is under the floorboards and sits on the floorboard supports. The gearbox tunnel sits on top of the floorboards. Lonnie TF7211 image: Here is how I believe that you can modify the Moss rebound rubber:

|

| LM Cook |

| image: The Abingdon Spares rebound rubber is thinner and compresses thinner than the Moss rebound rubber. See how little rubber is visible. Notice that the cupped washer is mounted with the convex side against the rebound rubber and the nut fits inside the concave side. NOTE: Check your mounting bracket. A weld was broken on mine. I have seen other mounts that had the entire end missing or one of the mounting ears missing. Repair if necessary before installing into your car. See a couple of posts about the problem in the archive thread linked in my previous post. Lonnie TF7211

|

| LM Cook |

| Thanks Lonnie for the additional pics and link. We seedm to be having the exact same issue. I have both styles of the clevis rubbers. The squared edged one was in a Moss rubber kit that came with the car and must have been at least 10 yrs old. the rounded profile came with my new Moss clevis. I did have the cup of the washer facing upward which to me seems correct to help keep the rubber from splitting as it ages, but I could be wrong. I will profile the bottom outside corners of the blocks and see if that helps any but I think for it to work and have the driveline clear the leading edge of my tunnel I will need to shave quite a lot from the bottom and sides to gain room Did you actually measure the profiles of the blocks ie ASL VS Moss and note any difference? Was one a softer compound vs the other? Bill Chasser Jr TD4834 |

| W. A. Chasser Jr |

| Bill - I didn't measure the Moss rubber or the A/S rubber, but I did hold them side-to-side and I couldn't feel any difference in dimensions. They seemed about the same density, too. Both required grinding the edges to fully fit inside the bracket, My Moss rebound bumper was not rounded. I used the Abingdon Spares rebound. It seemed softer and thinner than the Moss rebound. If you don't buy the complete Abingdon Spares mount, then maybe you should at least buy the A/S rebound bumper. FWIW - I feel that the A/S rebound is made incorrectly. The rounded edge of the rebound is on the side that does not contact the bracket. The edge that fits against the depression in the bracket is square. But it worked, so I didn't fret over it. I did not need to use brute strength to tighten the nut enough to insert the split pin. "Firm, but not crushing." I tightened the nut into position while I was squeezing the mount to the gearbox with two bar clamps. Regarding the cupped washer, A diagram in the WSM shows the cupped washer in the correct position. It should be oriented so that the edge of the washer won't contact the bracket as the rubber is compressed. A flat washer would accomplish the same purpose. See "Image" below. If the U-joints are still too near the tunnel after you get the rubber sorted out, then I guess you could add shims between the mount and the floorboard supports to raise them and the tunnel. Others can give you better advice on that subject than I can. I don't know how much the rear of the gearbox will settle as the rubber ages. I seem to remember a thread in the archives about the U-joint hitting the tunnel. I believe that it was posted as a question to track down the source of a metallic sound in the cockpit. Lonnie TF7211 image - cupped washer orientation ("B")

|

| LM Cook |

| I rounded the bottom outside edge and the mount went together easily outside the chassis. Didn't need clamps. It just went together nice and easy. I have yet to hoist it back in the car as I need to hook up the brake peddle return spring and need all the room I can get. Wish I had done this before the tub was installed. Yikes. Doesn't look like fun. I couldn't get my arms contorted the right way or see what I was doing while in my back. The race shop next store has a lift so I will see if I can get it in the air for a half hour or so. |

| W. A. Chasser Jr |

This thread was discussed between 05/04/2015 and 06/04/2015

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now