MG-Cars.info

MG TD TF 1500 Timing mark BETWEEN links on 51 TD engine BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

MG parts spares and accessories are available for MG T Series (TA, MG TB, MG TC, MG TD, MG TF), Magnette, MGA, Twin cam, MGB, MGBGT, MGC, MGC GT, MG Midget, Sprite and other MG models from British car spares company LBCarCo.

MG TD TF 1500 - Timing mark BETWEEN links on 51 TD engine

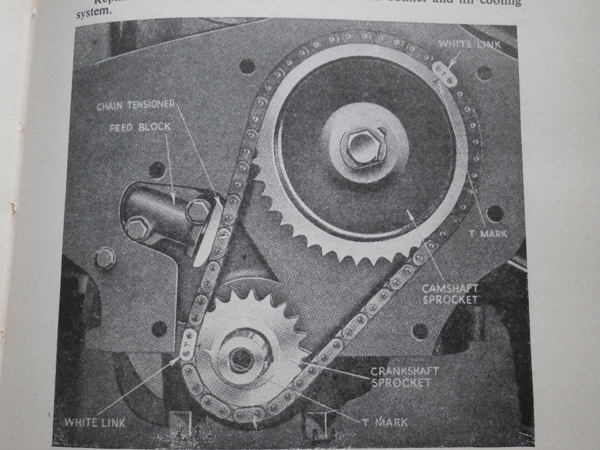

| OK, here's my question. When I removed the motor and disassembled, the T mark on the crankshaft was BETWEEN two links, while the T mark on the camshaft was directly on a link. Forget "white links" as this was probably a later chain and you just can't tell. However, there are 13 links between the T marks, as described. It's just that shouldn't the crankshaft T mark be directly on a link? If this is the case, how come this engine ran fine for 20 years with the chain set this way? It's been reassembled exactly this way so it is the same as it was before... Here is a photo taken prior to rebuild, it looks pretty much the same now. Everything I've read seems to indicate both marks should point to a link, not BETWEEN links. If both marks were between links and the link count between (13) was correct, I would imagine that would be OK. But how can one mark be between links and the other ON the link?

|

| Geoffrey M Baker |

| Geoff, If timing is THAT critical for you, you can always order the B&G specially-made sprocket for £156 that will allow you to adjust valve timing almost infinitely. Have a look at http://www.ukmgparts.com/product/td-midcat-13-td2-engine-internal-parts/adjustable-sprocket-set-xpag-xpeg-aaa5664ka Gord Clark Rockburn, Qué. |

| Gord Clark |

| It's not a question of critical, Gordon; I just want to make sure it's all going back together correctly.... |

| Geoffrey M Baker |

| if its a standard cam profile, and you know the lift, fit a cam timing disc to the crank nose, find tdc, put a dial guage on the lifter pushrod and max lift should be at ... something deg, off to feed the chucks, somebody will know ... |

| mog |

Your picture was taken at a random place in rotation and you only have 6 or 7 links between the marks on one side. That has no bearing whatsoever on initial set-up of the marks. The engine would have to rotate many times for the marks to align again. Suggest getting a factory manual, read, understand, and install per picture attached- 13 links on the right side and 15 on the other. George

|

| George Butz |

| Geoff, I don't think you have a problem. All XPAG chains are made the same way. It's the same distance between any 13 links. If you want/need to change the valve timing you need to change the position of the keyway, not the chain. I don't think the precise location of the base of the letter "T" is intended to indicate any specific timing variation. Bud |

| Bud Krueger |

| My question is that all pictures - and every discussion I've seen here - shows the T marks aligning to the center of a chain sprocket on both gears. My engine, NO MATTER how many times I turn it, will always show my crankshaft alignment to be one tooth - or half a sprocket - off the alignment shown in the book etc - it lines up BETWEEN chain links, while my camshaft mark lines up correctly. Doesn't this indicate that my engine is a couple of degrees out of whack? I mean, if we all have the same gears and the same chain, then my setup is one cog, or tooth, or half-sprocket, off what everyone else's is. This is how it came out when I disassembled (and took pictures) and this is how the shop reassembled it. Does it not indicate that the whole setup is one or two degrees off? If I remove the timing chain and turn the crankshaft one tooth clockwise, I would now have a chain that lines up correctly, with both timing marks pointing to a chain link, with 13 links between, I would have an identical setup to everyone else's... Which isn't a problem, but does this suggest that my engine has spent the past 30 years running a degree or so retarded (or advanced)? It seems like there is only one correct way to do this, and mine is not set up correctly... |

| Geoffrey M Baker |

| The cam may have been indexed 1 tooth out to correct a machining inaccuracy. This, combined with offset keys will put the cam in the correct orientation. If your car has run to your satisfaction, why worry. When these cars were made there was no CNC machining so great variance in accuracy. Ray TF 2884 |

| Ray Lee |

your cam looks off, here from blower

|

| mog |

| Geoff, I wouldn't be surprised if the 'T' stamping isn't there stamped into all new crankshaft gears. Does anybody have a new one? Bud |

| Bud Krueger |

notice measure from left side.

|

| mog |

timing.

|

| mog |

| Both gears have visible T stamps, Bud. So far we have the possibility that the cam and crank were offset intentionally (Ray's suggestion) to offset some machining problem. OK... Well, let me ask the experts another question. If I set up an engine that was normal in every way with one tooth out (as mine appears to be)... what would be the result? Would it run OK but just be somewhat advanced or retarded in timing in general? And if I set it back to what looks like correct parameters, will I do anything but change my timing issues slightly? |

| Geoffrey M Baker |

| Geoff, You can't tell whether the chain is correct, because the engine must be turned numerous (20) times before the marks re-align and you have the correct number of links on each side. George Butz is correct, your picture shows an engine that is in a random position. Your "T" mark on the crankshaft sprocket can certainly end up between chain links every other 360 degree turn of the sprocket. If you want to check cam timing---Two options: Start turning the engine a lot of times until the links line up per the WSM or ----- remove the sprockets/chain, align the cam and reinstall them per the book. I agree that setting up the cam timing is an important step in assembling the engine. If your machine shop didn't set it per the book then you should go through the steps to do it yourself. Also, if you remove the chain, be sure to confirm that the small oil hole in the chain tensioner is clear. I found two of my engines plugged by crud. |

| Richard Cameron |

| Rich, thanks for the info. Here's what I can see so far... you are correct, The T mark on the crank moves through two positions every other 360 degree turn. In one it is aligned to a link. In the other, it is between two links. When it is between two links, the T on the camshaft is in the apparently correct position and there are 13 links between the two - so it is one tooth off from being correct. When the T on the crank aligns to a link, the T on the camshaft is wildly off and is in fact upside down, with no chain piece engaging it at all. I rotated the engine some 40 times and found the same situation, every two rotations. The machine shop set it up the way I left it and I left it based on the way it was when I took it apart, which was one tooth off. I marked the spot between the links and they reassembled correctly - leaving me with the same problem we had before the engine was disassembled. So I'd still like to know what happens when you run an engine with the cam/crank alignment one tooth off? I am guessing that it runs OK, it is just either advanced or retarded in the sequence slightly, which was probably compensated for by running rich? I'm still leaning towards removing the cam gear and rotating the chain one tooth back so that it matches the alignment shown in the book. |

| Geoffrey M Baker |

| Geoff; I think you have it correct. The engine will run one tooth off, not to spec tho'. If it is set correct, you will have to adjust timing to compensate for the error. .... CR |

| C.R. Tyrell |

| The engine might run one tooth off depending on which direction, but I don't think it would be satisfactory even at a best ignition compensation setting. The owner would know something was wrong immediately. |

| Richard Cameron |

| Geoff, Have you tried removing the gears and replacing them (and the chain) exactly as per the manual? If so, do that. Gene |

| Gene Gillam |

| Most likely DPO or "mechanic". Set up by the book. Off a couple degrees will result in either lousy low end or top end performance. George |

| George Butz |

Yes, don't mess around at this juncture--- Release the rocker tower bolts and remove the lifter/push rods so you can turn the cam to set it like the book shows. Any white links on the chain will probable not be usable because only NOS chains from the era were correctly made with white links in the correct place. Just make sure there are 13 links between the "T" marks on the tensioner side and you'll be correct. |

| Richard Cameron |

| I released both crank and cam gear and rotated and reset. Problem solved. 13 links between the T marks, on the tensioner side. Now, I have some gaskets to redo... |

| Geoffrey M Baker |

| Just want to add, the machine shop replaced everything exactly as I had marked. This wasn't their fault, and it wasn't mine either. Problem was, it was one tooth "out" before I disassembled. This is just one more problem that's been around for at least twenty or thirty years. I can't wait till I have this beast fully up and running again at factory specs... |

| Geoffrey M Baker |

| Geoff do you know what sort of cam you have? If it's a performance cam it may require the existing setup. As Mog says "If it's a standard cam profile" ... With a standard cam I'd go by the book but if the car performed well prior to tear down it may well have a "warm" cam. If so I'd be loathe to alter the existing timing. If it was me I'd try & determine the status of the cam before I altered the timing. Ray also mentions offset keys. Do you know if one is fitted? The chain tensioner lockwiring looks like it was done by someone who could handle a pair of lockwiring pliers but on the other hand the lock washer on the cam looks like it's seen better days. As this wasn't replaced I also wondered if the chain is new? Maybe you should ask these questions of your engine rebuilder. Cheers Peter TD 5801 |

| P Hehir |

| Peter...iIf it was a performance cam installed by someone who knew what they were doing they'd have more than likely used an offset key instead of offsetting the gears. I have a feeling that what happened was Geoff didn't understand the relationship of the timing marks and the chain when he took the photo and that if the engine had been rotated around it would have as shown in the workshop photos it would be the way it is today. |

| Gene Gillam |

| Gene, I'm sorry by confusing things by posting an earlier photo of the gears which as pointed out, bears no relationship to the proper timing setting. However, I did go through a process - as described earlier, where despite doing 60 revs or more, found that the timing position was *consistently* one tooth off. No amount of further rotation would demonstrate anything but the fact that it was improperly set to begin with. Because it was one tooth off to start, the machine shop (using my instructions) reset it to that setting. (I had marked the chain links for them, using a marking paint, to show where it matched to the gear stampings). I discovered this before stripping down the engine, but didn't think about it too much until we came to rebuild it and was checking everything against factory and book settings, and wondered why the gear marks didn't match exactly to the chain links, as shown in the books. I've fixed it now. I imagine for the past 20 years it's been slightly off, which required adjusting distributor and valve settings to compensate; as long as my dad had the car, he reported it running rich and somewhat problematic. I got it running better, but it was still never quite right. Hopefully, now this is done, from here on out we can really "dial" it in to the ideal settings. Anyway, on to the next project... waiting for sump gasket, new water pump and new crank pulley before closing it all up and installing it into the car... |

| Geoffrey M Baker |

| Fingers crossed for you Geoff...I'm really want to see a youtube start! |

| Gene Gillam |

| Fingers crossed for you Geoff...I'm really wanting to see a youtube start! |

| Gene Gillam |

| "Problem was, it was one tooth "out" before I disassembled." This is why I go WAY FAR out of my way to find cars that haven't been botched up by former 'restorers' who's idea of a restoration is chicken wire and a wad of fiberglass. Some cars have no hope of finding documentation nor assistance. ..... |

| MAndrus |

| Geoff if you haven't replaced the timing chain I'd recommend that you take the opportunity to do so. Also ensure you fit the crank pulley before the sump. DAMHIK. Cheers Peter TD 5801 |

| P Hehir |

| Hi Geoffrey, Your cam timing was correct before the engine was dissembled! I have attached a copy of your own image with some added lines to show that if the engine was rotated anti-clockwise a part-turn, there would have been thirteen links on the left .... which is correct. Bob Schapel

|

| R L Schapel |

| refer to the work shop manual, the engine will need to be rotated 20 times before the marks will again line up. The WSM also has intake & exhaust valve timing figures BTDC & ATDC. Checking clearance or valve lash for this operation may or may not be 012" or .019". I remember a post stating .025" or .027" I might be wrong. For the later cam it also mentions inlet valve open ATDC. If you are one tooth off it will result in about 17 crankshaft degrees advanced or retarded. Not acceptable, it will run, but barely. Offset keys are used to fine tune the cam, usually only 2-4 degrees, if needed. I have offset keys in stock. Best way is to use 2 dial indictors, one the piston, or timing marks on a degree wheel mounted to the pulley, & one on the lifter, or valve spring retainer. |

| Len Fanelli |

| Geoffrey, PLEASE, PLEASE, set your timing gears up as this photo and upload to the site.Note the keyways are at the top. It is a PIA resetting timing wheels while the engine is in the car. Ignore the blue Hylomar it was removed before assembly. I always photograph the set up before closing the engine, it saves the "did I" moment later on. Ray TF 2884

|

| Ray Lee |

| Nice job Bob Schapel! |

| Gene Gillam |

| Thanks Bob... Not sure how I got that wrong... |

| Geoffrey M Baker |

| Yes! Thanks Bob, it can be confusing, even for people like ME. I will put this in my files, & refer to it, as I am about to build a customer's engine. |

| Len Fanelli |

| Biggest trap that catches most is having the engine upside down when you count the number of chain links. Beware! |

| G Evans |

This thread was discussed between 18/08/2015 and 21/08/2015

MG TD TF 1500 index

This thread is from the archives. Join the live MG TD TF 1500 BBS now