MG-Cars.info

Triumph TR6 Horn installation 71 TR6 BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - Horn installation 71 TR6

| Hello everyone. New member here. I just purchased a partially assemebled 71 tr6. I have most of the parts including the 2 horns. I have the Haynes and Bentely Manual but I can't seem to locate the mounting points. I did a search of the archives and didn't turn up anything. If anyone has apicture of them under the hood that would really be helpful. I take it they are mounted somewhere in the front corners?? Thanks in advanced |

| A Vandergoot |

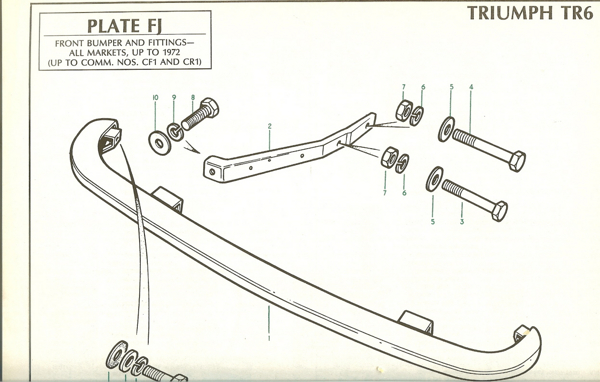

Someone will correct me if I am wrong, but....IIRC it mounts to the 2 threaded holes that are nears the top of each of these (#2)

|

| Don Kelly |

| Sweet Don!!!! many thanks. Now I know what those braces are for that were sitting in a spare parts box!!!!. Al |

| A Vandergoot |

| A. You should download the Blue book from the Raodster Factory which has all the schematics you will need to assemble the car. If you are interested and Don or Rick or Doug are feeling in the mood, they can send you a CD with a bunch of TR6 related technical information. Let them know if you are. Welcome to this BBS. Good luck with your project. Mike Petryschuk 69 TR6 |

| Michael Petryschuk |

| Don't even know if I have that CD any more. Just downloaded it to my hard drive . If that crashes, I'll just sell the lot |

| Don Kelly |

| A, Share your email address and I'll send you most of what you need for your restoration. db dbaker04ATaolDOTCom, remove and replace the at and dot with proper symbols and that's a Zero not an Oh. db |

| Doug Baker |

| Thanks Mike. Yup I have downloaded both volumes but somethings just aren't clear. Dons picture shows the brace but no image of the horns so sometimes a bit a of clarification is really helpful, which this list is great for. I don't have too many spare parts mostly seals (doors,trunk windows) that need to be replaced. The electricals are a mess though. Underneath the dash looks like a boars nest of wires. The car starts though, just needs me to go through it all. It even came with the factory hard top and it is not even rusty!!! I will need to put the TR on the floor jacks to better mount the front body parts. Thanks again for all the great help and keep those post coming, as those and the archives are a great resource. Don, Rick or Doug, any info you can provide will be appreciated, but only if you have the time. If there is a cost involved let me know. Thanks again Al My email is van10@shaw.ca |

| A Vandergoot |

Al, here is a better pic

|

| Don Kelly |

| Yes that is the one!! Thanks Don. uhh where are your horns? Al |

| A Vandergoot |

| That's pretty funny |

| Don Kelly |

| Couldn't resist. ;) |

| A Vandergoot |

| AL "uhh where are your horns?" we don't ask Don questions like that. Ya gotta love it when another '71 gets some pampering AND he's a Canuck! I have a dash drawing/schematic on a Download site for you to go and get. I put it up there back in May of this year and just noticed I have had 24 downloads. The 2 files (.rar) are ones that I cleaned up and are generally not found anywhere. Here it is http://uploading.com/files/d7394213/Wiring.rar/ Click on the Free download and go get a coffee:).....hey it's free. I* am not sure if you have it or not but there are good schematics of the wiring of a TR6. Sounds like Doug is going to send you a copy of CDII. The schematics are on the CD. I can send him one Doug if you want. I have about 6 copies burned that I am going to take to my car club...I can keep one to send to Al. It is way to big (over 4 GB) to e-mail Al. Rick |

| Rick Crawford |

| Don't need the Schematics on CD ,just go here http://www.advanceautowire.com/tr2506.pdf What's the commish # of the car? |

| Don Kelly |

| Hi Rick thanks for all the info. I have downloaded the file so I'll have look to see what's what. Don, I have that schematic link in my favourites. I can actually kind of understand it. Rick and Doug, If there is a cost to sending anything let me know so I can forward you the money. Don Com # CC 62854L made March 1971. As it is Thankgiving Monday here in Canada and I'm off, I'll start sorting though the wiring in as much as I'm able to. Thanks guys for all your help. A last question, I stumbled on a website that posts the different bolt sizes for specific parts for a TR6 in XL format. Any other sites out there that you are aware of. Hopefully I can source some fasteners locally. Thanks again. |

| A Vandergoot |

| Think Doug has made some kind of a nut chart too |

| Don Kelly |

| Just thought I would shoot a picture of my TR. Unfortuantely the previous owner painted it a none stock color. Originally it was red. Al

|

| A Vandergoot |

| Al You are welcome. She looks very clean. Did she have a body off restoration? "I stumbled on a website that posts the different bolt sizes for specific parts for a TR6 in XL format. " What is the site address? I am always looking to add to my TR information data base. That would have been handy when doing my restoration. I had to use the GREEN book to get my sizes and lengths. I know Doug has an XL document (the nut chart) on the CD My '71 is comm# CC65060L....May. When I was doing my restoration I went to CarQuest and bought boxes of nuts, bolts (including different lengths), and washers for all the sizes. If I recall only about $60.00. They can order in what you want if not stock. There are many WEB sites out there for TR6s including different forums. Al e-mail me a snail mail address so I can fire off a CD. I may as well do it Doug since he is in Canada. Obviously remove the anti-spam stuff in my e-mail address. Rick |

| Rick Crawford |

| Rick, I've already prepared a CD for Al and it's on it's way, but with crossing the border it may take a day or three!! Al, there's an excel spreadsheet of most of the fasteners on the CD. Rick, you got out lucky. Of course, I opted for stainless so my fastener cost is several times what you paid. There are several sources for various fastener packages; one in the UK for the wings in stainless. Good photo Al, but much too much like Rick's. Need a darker blue like Don's!! Good luck with your restoration effort. db |

| Doug Baker |

| Thanks Guys. The PO says it was frame off. It all looks very clean. He re-did all the interior mats/carpeting and upolstery excepting the seats. My stainless exhaust system just arrived so I'm going to focus this weeken on trying to get that on. I think everyone on the list must know http://www.buckeyetriumphs.org/ This is the site that had the xl worksheet for bolts/nuts doesn't say corse or fine thread though. Doug was this the website you used, as he replaced all his fasteners with stainless? |

| A Vandergoot |

| Al, Lots of really good information at Buckeye's site and much of it is on CD II. I did not use the XL SS for my listing of the fasteners. If you'll note, the list from Buckeye's is very short; does not include very many fasteners; just the primary ones. I used the Triumph Supply Manual and TRF's VOLs I & II to identify the fastener then physically checked the diameter of the fastener, the length, grip length and confirmed TPI and NSF or NSC. Almost NO NSC fasteners in the TR-6. I then listed by nomenclature, application, nominal size and TRF part number. My list is not complete, missing many of the internal engine fasteners which I purchased from APT-rod bolts, bearing journals nuts, head bolts, etc and several area which I have not yet dissasembled such as the transmission and the differential. Having said all that though, it's a pretty exhaustive list and does include those from the Buckeye site as applicable. There are several sources for stainless, but be careful to insist upon Made in USA where you can. Inferior products from China are rampant so buyer beware. Steve Pike is the expert on the metalurgical concerns. In some cases, cadimum plated is preferred to stainless due to the increased electrical potential differential (read corrosion potential) which arises with stainless in those situations. I sought absence of corrosion and have been willing to pay for stainless, but it's not the best choice in every case and where drive train or safety is critical, examine closely to make sure the softer stainless is sufficient for the application. For example I used APT bolts for the flywheel, not stainless. db |

| Doug Baker |

| uh...upon reflection (and checking the SSs) that's UNF, Unified National Fine and UNC, Unified National Course and it's ARP (automotive Racing Products, Ventura California) not APT!! Hope you knew what I meant dispite my errors. db |

| Doug Baker |

| Looks nice Al. Looks like Rick and Don and Doug have gotten the info you need. You can get grade 5 and grade 8 UNF and UNC bolts and nuts at Fastenal, Brafasco for good prices. Various lengths available. They also have nyloc nuts. TR6 is 1/4 inch , 5/16 inch , 3/8 inch diameter UFC predominantly. I recommend you buy a tap and die kit with UNC and UNF size to help celan up threads of nuts and bolts you want to reuse. |

| Michael Petryschuk |

| Any SS fasteners for suspension and the like, I would use Spruce http://www.aircraftspruce.com/ A little pricy but safer than the lower grade SS you get at most places. I unfortunately didn't use the correct hardware and will one day tear it all apart to use the correct grade |

| Don Kelly |

| Life's too short (and can be made shorter) to put up with bad fasteners. Bear in mind that "bad" is a relative term, it can be a perfectly good fastener for some application but terrible in others. Easy stuff first, yes, Doug's engine stuff is made by ARP, but I can see why APT is mentioned as they sell ARP stuff and actually have the bits "kitted up" for our LBC applications by careful perusal of ARPs offerings, then playing mix and match to suit us instead of say, the small block Chevy crowd. Now for the gritty stuff. For the most part, I don't really like to use CRES (aka stainless steel) fasteners unless there is some compelling need to do so. CRES is much more prone to galling when joined against CRES, and if you've never had to go drill out blind CRES fasteners, trust me, you want to keep it that way. You have to be careful about the relative hardness levels to minimize this and that in turn offers up the potential of having a weaker joint than intended. The other downside is that most of the readily available CRES fasteners out there are an austenitic CRES and they are either relatively soft with low yield points even though they have relatively high ultimate strengths, sort of like a metallic taffy if you will. To get away from this, you have to get ones that have been sufficiently coldworked to drive the yield points up and even then you are still below your good old alloyed steel fasteners as far as strength goes. If you really want to go CRES and you need high strength, you get into CRES varieties that are not readliy available to us mere mortals and if you do find them, be prepared to give the supplier a guided tour of your wallet. If the application is lower loads, there is a low chance of galvanic corrosion in the specific application(s)and you don't mind spending more, then go for it. In general, I like to use the AN3-20 series of bolts that you can get from places like Aircraft Spruce or Coast Fab. I don't know how things are in Canuckistan, but here in Baja Caņada I can get AN bolts from Spruce for less than it costs to get inferior stuff from the hardware store. Plus I get the advantage of being able to select my grip length in 1/16" increments, you can't even do that out of Roadster, 1/8" increments is as good as it gets and even that is spotty. Typical hardware store stuff is on 1/4" increments. As for strength, the AN3-20 stuff in alloy steel falls between your Grade 5 and Grade 8 ASTM/SAE fasteners and that is plenty strong for most of the Triumph applications. They also offer up aluminum and CRES in the AN3-20 series, but see above on CRES, as for aluminum fasteners, well we're not building aircraft here so the weight savings driver is so minimal that for all intents and purposes it just isn't there. If you just have to have that Grade 8 strength, then you go pony up for the NAS1103/6203 fasteners. They're a little stronger than a Grade 8 and the quality is much better than the stuff you find at the hardware store or even places like one our local fastener supply houses called Threads for the South. Here's a freebie copy of the AN3-20 courtesy of Diamond Fasteners: http://www.diamondfasteners.com/specs/AN3THRUAN20-REV12.006281.PDF Probably bored you to tears by this point so I'll leave it at that. |

| SteveP1 |

| Steve, love a good nuts and bolts story |

| Don Kelly |

| Mike, A couple of points...most of the fasteners on the TR-6 are UNF not course.1/4-28, 5/16-24, 3/8-24, 1/2-20, etc. I'd disagree with a tap and die set, but swear by Sears Craftsman thread chasing set. I've about worn my out!! Has all but the very few sizes you'll need and I VERY strongly recommend chasing every threaded hole/bolt before final assembly. Use a tap/die if you don't have the thread chaser but be aware that it may cut new threads and you do not want to do that; just clean up the old threads. db |

| Doug Baker |

| Thanks Doug I actually meant UNF. Don't know where my mind was then. It gets worse with age I tell you. Tap and Die worked well for me.But I agree with the point. You do have to be careful. |

| Michael Petryschuk |

| Mike Et Al. Good advice from everyone with regards to the bolts. The chassis bolts I pick up at Lordco are not SS but rated #8 strength wise. I do have the Air craft spruce catalogue so if I do decide to go that route I'll follow your lead. Over the weekend got the TR up on the jack stands and cut the old exhasut system off and started to nstall the new one. I don't have the stock clmaps and the 2 inch circle clamp for the pipe is a scarce animal. Looks like I will substitute a motorcycle exhaust clamp of the appropriate size. Cheers Al |

| A Vandergoot |

This thread was discussed between 08/10/2011 and 18/10/2011

Triumph TR6 index