MG-Cars.info

Triumph TR6 REAR BRAKES WONT BLEED BBS discussion at MG-Cars.info

MG-Cars.info

Welcome to our Site for MG, Triumph and Austin-Healey Car Information.

Recommendations

Parts

TR parts and Triumph parts, TR bits, Triumph Car Spares and accessories are available for TR2, TR3, TR3A, TR4, TR4A, TR5, TR6, TR7, TR8, Spitfire and Stag and other TR models are available from British car spares and parts company LBCarCo.

Triumph TR6 - REAR BRAKES WONT BLEED

| Greetings, I've replaced the rear wheel cylinders and upgraded all flexible lines w/ Teflon and SSteel. After rebuilding the master cylinder I went through the routine of bleeding the system starting at the right rear, etc. I'm using a Mighty Vac to bleed the system but I get no fluid out of either of the rear brake bleed screws. The system will not hold a vacuum which suggests an open in the rear brake piping system. I get fluid out of the front brakes but not out of the backs. What is the best next step in finding the vacuum leak. I thought of pressurizing the rear system w/ shop air and spraying soapy water on all of the pipe joints and rear piping. Is this correct or is there another way to rectify this problem. Oh, yea. I've never had decent back brake stopping power. I've had a knowledgeable mechanic replace the rear wheel cylinders in the past and it was better for a bit, but did not last. What am I missing here? Any help would be appreciated. Thanks, Metrymike 504-782-+8535

|

| m n buford |

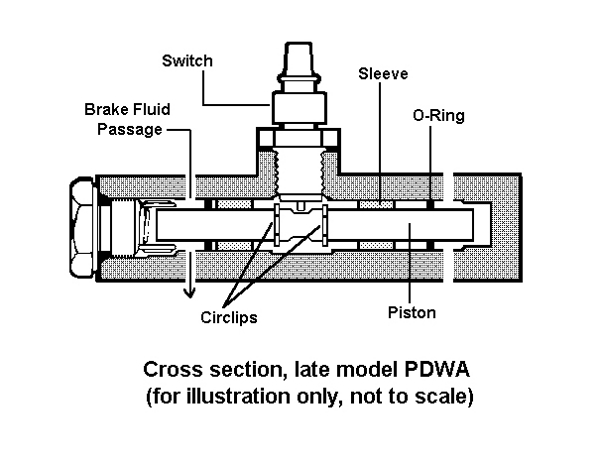

| M I wounder if your PDWA is not centered properly. Or it is just plugged up and not allowing fluid to the rear brakes properly. There is a procedure on the repair of this part with cautions on the procedure. It is easy to check if it is not centered. I also have a Mighty Vac and find it helpful when one is by himself. HOWEVER.....I have found that the unit likes to suck air when attached to the bleed screws. This air comes around the threads of the screws and not much can be done about it. I find once you have got rid of most of the air and you get mostly fluid comming from the bleed screw, I resort back to having help at the brake pedal. Let us know if your PDWA is at fault. Rick

|

| Rick Crawford |

| Rick, thanks for the input. I too suspect the PWDA, or a bubble lock up in the rear brake portion of the Master Cylinder. I intend to start at the MC outlet for the rear brakes with the MightyVac. If I get fluid out of the MC then I'll go to the rear side of the PDWA. If I get no fluid out of the PDWA then I'll spend some time trying to get the PDWA up to spec. If all of this doesn't work, my latest idea is to install a Schroeder valve in the MC cap and use my bicycle pump to put 5 - 10 psi in the system. The air pump would apply positive system pressure which is the opposite approach to using the MightyVac and creating negative pressure. Using positive pressure should show leaky fittings or a busted pipe. Hope this finds you in a fulfilled mood. Peace, Metrymike 504-782-8535

|

| m n buford |

| Rick, About those bleeder screws leaking air ... the MightyVac manual suggests greasing up the threads on the bleeder screws before final installation. The tech at the shop that manufactured my Teflon/Stainless Steel flexible brake lines said that he uses this method to stop air leakage. Peace, mb

|

| m n buford |

| Grease 'em with what? db |

| Doug Baker |

| Doug I am not going to touch this one...hello Don? Rick |

| Rick Crawford |

| Yeah, I guess I did leave an opening there!! I figured Red Rubber Grease, but maybe Don'll suggest something like petroleum jelly!! db |

| Doug Baker |

| Group, Using the stomp and pomp method I managed to get fluid out of both rear wheels. I noticed fluid coming out of the booster and the floor as the brakes were pumped ...so I may have blown the MC rebuild. Now I have a direction to follow in the failure analysis. Nice site I'll be back. Peace, M Buford |

| m n buford |

| Well now, It seems we have a full brake pedal! Yea! Thanks for the help everyone. Lessons Learrned: * MightyVac has sealing integrity issues w/ the stock OE hose included w/ the kit. Even w/ applying grease around the nipples per the manual, the hose/threads allowed air bubbles into the effluent The MightyVac worked about 70/30 successfully, and I will keep the tool for further uses on both positive and negative pressure diagnostics (Think Diaphragms.) *The Stomp and Pomp Buddy Plan works again. This proven method as used for centuries has once again proved it's value for hydraulic systems. It only cost me a Orange Beurre Blanc w/ shrimp over tuna, and haricort vert home made meal. *The torque required to reattach old grungy existing male threads by screwing it into a new gootntight virginal wheel cylinder can fool you. Upon rear wheel reassembly, I tightened up the brake line into the wheel cylinder to a torque where I thought I had sealed the line. Previously, I thought I had removed all of the grit from the threads w/ a brush and brake cleaner fluid. Nope! After several more turns the nut bottomed out and refused to move. Presto! Problem solved and the system has a full pedal. Has anyone tried out that Kentucky Jelly? |

| m n buford |

This thread was discussed between 08/08/2009 and 15/08/2009

Triumph TR6 index